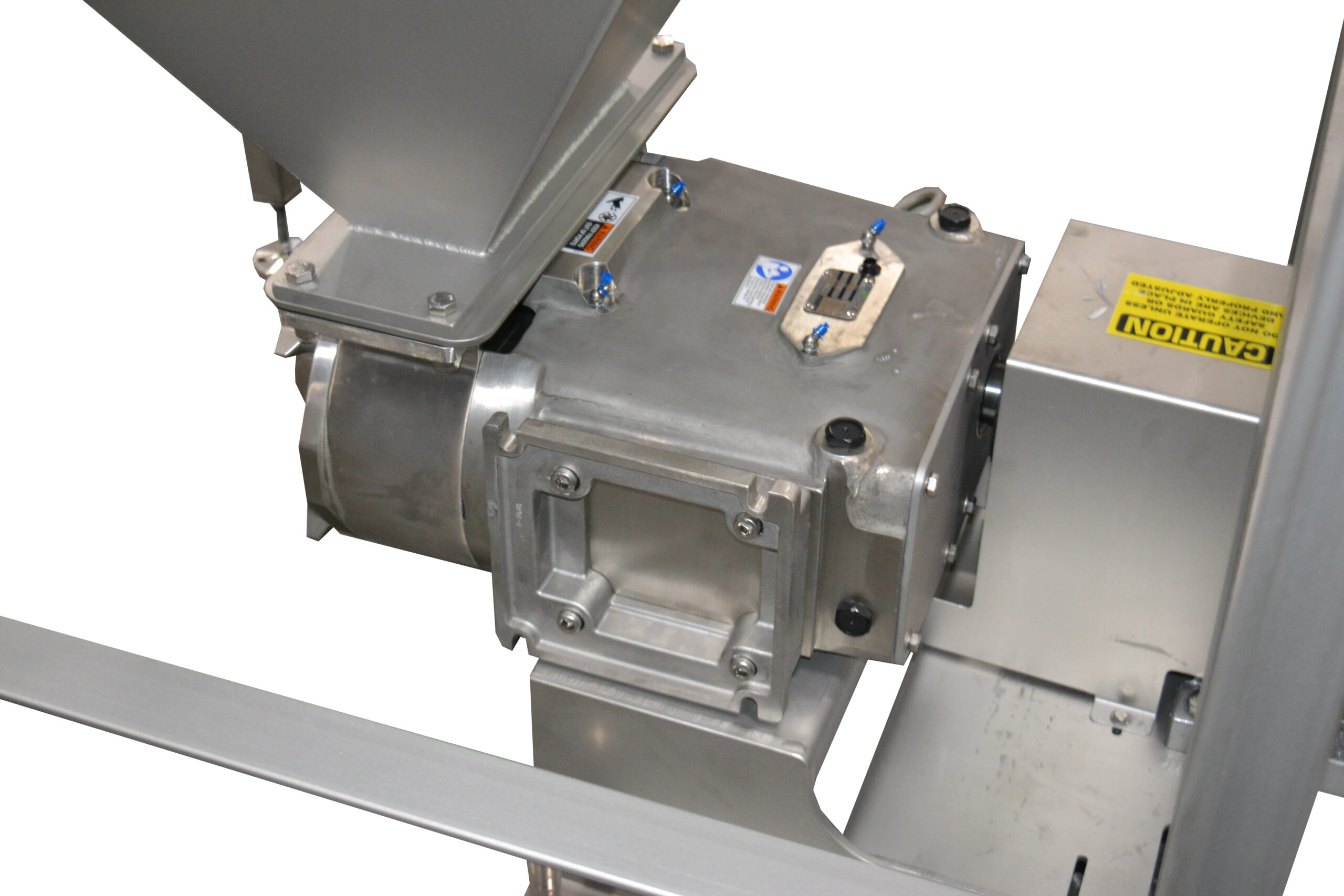

Pump Hopper

You can't risk stalled feeding or wasted materials impacting your bottom line. FPEC's pump hopper delivers continuous pumping and smooth material handling in demanding environments.

We customize each unit to meet our clients' unique operational needs and installation requirements. You can count on stainless steel durability and UL-listed controls for safe, consistent operation during every shift.

Dependable Performance, Easy Cleaning, and More

Any downtime you experience can quickly drain your revenue. Likewise, the risk of contamination can threaten consumer safety. And dealing with hoppers that clog or have complex cleaning requirements slows you down and increases your labor requirements.

Instead, you need a durable feeding solution that guarantees safety, reduces stoppages, and integrates seamlessly with the equipment you already have in place on your line.

An FPEC pump hopper provides smooth pumping to achieve this. Our sanitation-focused design and easy access for inspection address the practical challenges of operation. Your team will enjoy improved uptime and operational safety with pump equipment designed for the real world.

Technical Specifications of Our Pump Hopper

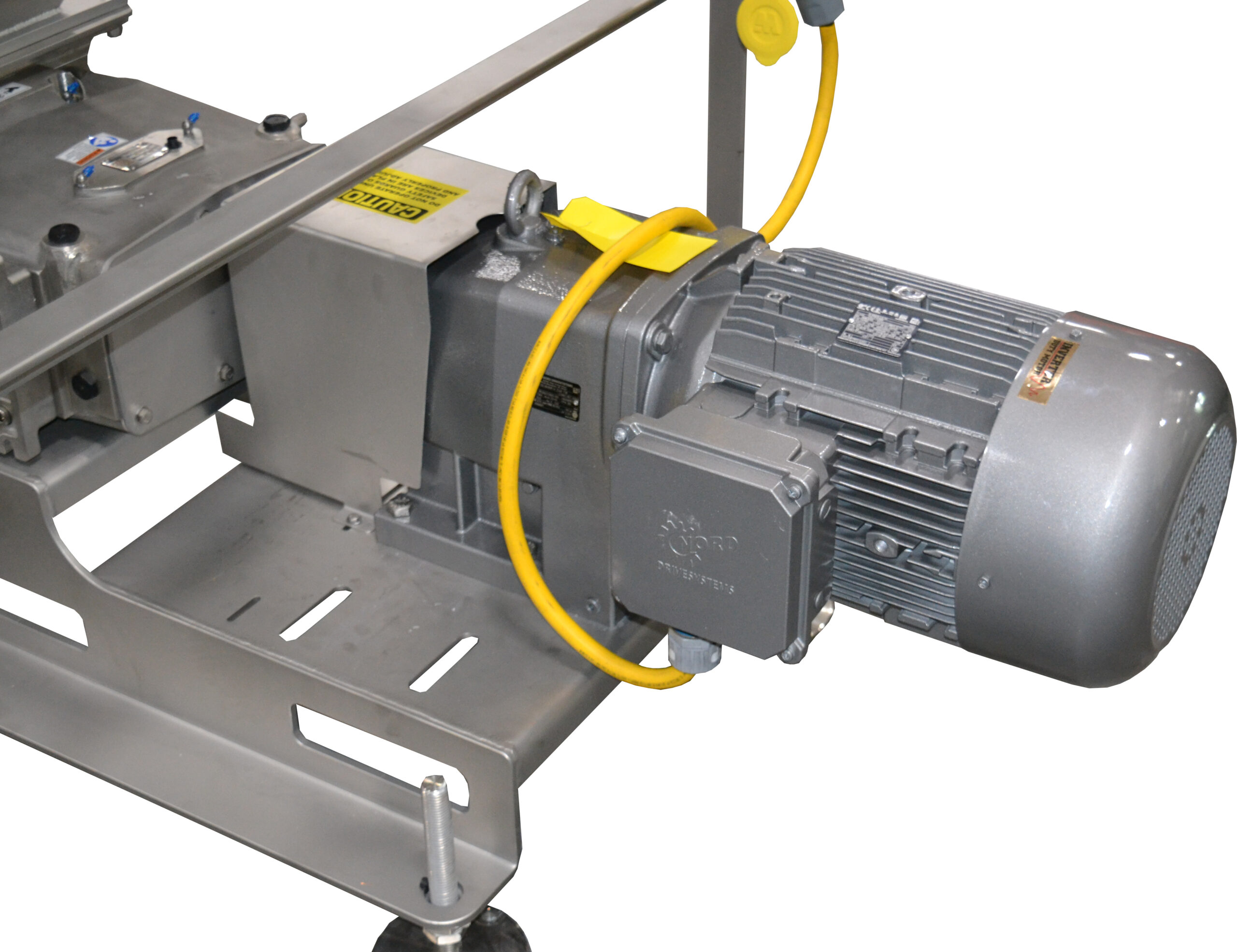

Every FPEC pump hopper is carefully engineered to match the client's specific facility and processing requirements. Durability, safety, and performance are built into each unit.

- Standard designs for positive displacement pumps

- Hopper capacities from 200 lb. to 10,000 lb.

- Can be supplied with or without a pump

- Portable or stationary carts

- Integrated or standalone controls

- 100% stainless steel fabrication

- NEMA 4X enclosures with slope top box

- All controls are UL-listed and built in-house

- Custom-built to your specifications

The wide range of configurations available serves to ensure reliable performance, no-fuss installation, and maximum uptime for your operations.

How a Continuous Pumping Hopper Can Benefit Your Line

aFPEC pump hoppers go way beyond improving efficiency. Your team will also enjoy an array of benefits related to productivity, user experience, and safety.

- Smooth operation: Steady feeding reduces downtime and limits surges to keep production moving

- Simplified cleaning: Sanitary design means fast washdowns and equipment free of contaminants when you change products

- Flexible bases: Adjustable height and both fixed and mobile bases ensure a perfect fit for your facility

- Dependable safety: Enclosures and access points allow for easy inspection and keep workers safe

- Straightforward maintenance: Robust build reduces wear and service interruptions to save you more on maintenance

These advantages can enable you to achieve the important metrics and ongoing improvement you aim for when implementing a high-performing pump hopper.

FPEC: Industry-Leading Engineering and Integration Since 1959

Since 1959, FPEC has been building food-processing equipment with a focus on engineering excellence and long-term reliability. As a family-owned company, we take pride in producing equipment that not only meets production demands but also supports the people who rely on it every day.

Choosing our pump hoppers — or any piece of FPEC machinery — means gaining more than equipment. It means gaining a partner invested in your success. Every system we deliver is designed to integrate smoothly into your existing operation.

Our role doesn’t end once the equipment is installed. From replacement parts to technical support, our team is ready to keep your lines running and your goals on track.

Success in Every Story

Hear about how FPEC equipment has helped our customers across the country.

FPEC equipment well designed and built to last. Maintenance on FPEC equipment is easier and we have less downtime with their equipment.

When i toured the FPEC plant I was amazed the craftsmanship and was surprised how large their facility is.

FPEC surprised me that they could not only build the equipment but also they build their own controls for everything, it makes it was easier to start things up.

FPEC tumblers really pick up marination!! We have great results using these tumblers.

FPEC solved my product flow issue, they designed a layout that moves my product smoothly thru process.

Find the Right Hopper for Your Line

FPEC makes it easy to find pump hoppers tailored to your specific needs. You can customize capacity, controls, mobility, and other features to suit your operations. Take advantage of easy integration and straightforward maintenance to maximize production without compromise.

Contact our team today to learn more about our pump hopper and other critical equipment. Our engineers are here to work with you to find the perfect match for your operation.