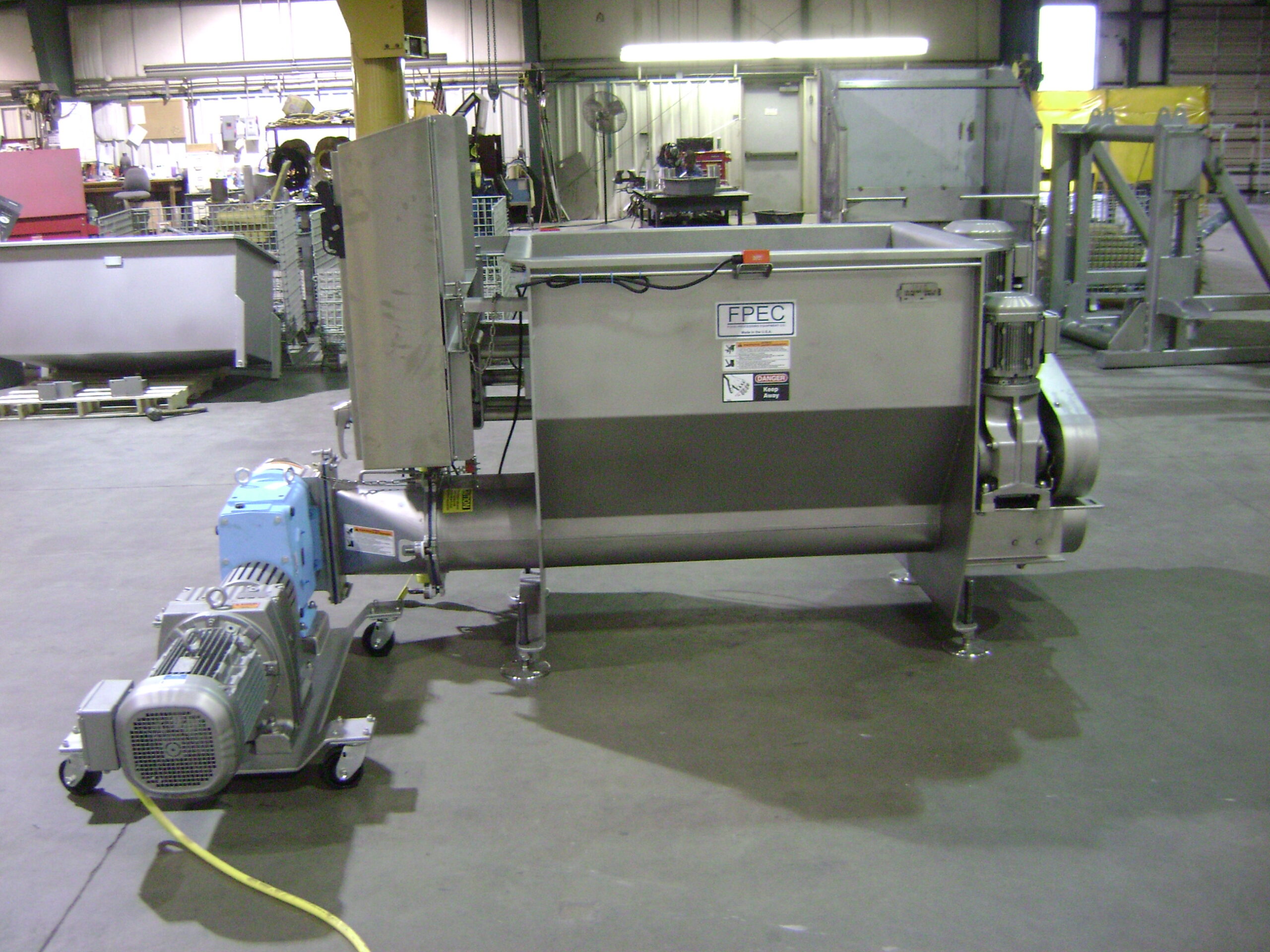

Food processors that work with highly viscous or delicate foods understand the difficulty of finding reliable equipment that won't sacrifice quality. FPEC's twin-screw pump system provides the smooth operation, high flow rates, and hygienic standards needed for demanding product-transfer applications.

Versatile and Hygienic Twin-Screw Pump Systems

Conventional pumps can struggle with viscous foods or mixed solids. Avoiding blockages and inconsistent flow requires a positive displacement pump solution that maintains product quality while adapting to changing line conditions.

The FPEC twin-screw screw pump system boasts a smooth, self-priming operation so your line can achieve consistent performance under high-pressure and variable conditions. Twin-screw pumps serve to promote the dependable transfer and superior hygiene needed in food production operations.

Twin-Screw Pump System Specifications

Our twin-screw screw pump systems are engineered to provide adaptable flow control, maintain hygienic conditions, and deliver lasting performance. Custom design and integrated controls mean your system will be perfectly suited to your specific process.

- Twin-screw design: The powerful yet gentle twin-screw design is highly effective for viscous products

- Flexible sizing: Hopper capacities from 500 lbs to 10,000 lbs support various specific production requirements

- High-volume output: Outputs up to 30,000 lbs per hour can accommodate a wide range of product types and characteristics

- Variable speed pump: Ensure efficiency across differential pressures and operate in any conditions with a stainless steel pump casing

- NEMA 4X enclosure: Slope-top housing resists moisture, simplifies cleaning, and protects operators

- Variable speed auger agitator: Prevents bridging, promotes reliable feeding, and improves overall pump efficiency

- Double mechanical seals: Extend your equipment's service life and reduce the risk of leaks, even under high-pressure operation

- 100% stainless steel fabrication: Enjoy long-term performance while meeting high sanitation standards and taking the difficulty out of cleaning

- Custom-built systems: Screw profiles, flow rates, and other details can be custom-designed to fit your process

These features highlight how twin-screw pumps work with both high- and low-viscosity fluids to satisfy the evolving demands of various industries.

Process Flexibility, Easy Maintenance, and Additional Benefits

A twin-screw pump system can promise a number of practical improvements for food processors. You stand to achieve both reliable performance and safe operation in the most demanding environments with a hygienic twin-screw pump system.

- Process flexibility: Capable of handling low- and high-viscosity fluids for any application

- Smooth operation: Twin-screw, non-contact design reduces shear and protects product quality

- Easy maintenance: Mechanical seals and accessible design streamline inspections and maintenance for your team

- Superior hygiene: Stainless steel construction and intentional design meet stringent food industry sanitation requirements

- Gentle transport: Screw pump operation prevents damage to solids in the mixture to safeguard product integrity

- Long-term dependability: Robust casing and screw profiles extend system life and support continuous operation

FPEC's top-quality twin-screw pump systems are made to deliver consistent results and benefit your operations in a myriad of ways.

Solutions Backed by Solid Operating Principles

At FPEC, we engineer food-processing solutions that meet the industry's high hygienic standards while offering rugged performance. We design and build our equipment in-house to suit our clients' specific requirements, placing special emphasis on efficiency, product integrity, and safety.

Videos

Playlist

Success in Every Story

Hear about how FPEC equipment has helped our customers across the country.

FPEC equipment well designed and built to last. Maintenance on FPEC equipment is easier and we have less downtime with their equipment.

When i toured the FPEC plant I was amazed the craftsmanship and was surprised how large their facility is.

FPEC surprised me that they could not only build the equipment but also they build their own controls for everything, it makes it was easier to start things up.

FPEC tumblers really pick up marination!! We have great results using these tumblers.

FPEC solved my product flow issue, they designed a layout that moves my product smoothly thru process.

Improve the Flexibility of Your Line With a Twin-Screw Pump System

The twin-screw pump system from FPEC can provide a robust solution when you need sanitary performance across a diversity of applications. If you value quality and efficiency above all else, your operation can benefit from top-performing equipment tailored to suit a range of viscosities, pressures, and flow rates.

Contact us today to discuss pump casing designs, screw profiles, and mechanical seal options. Our team can configure a twin-screw pump system to meet your unique procedural requirements.