Beef Processing Applications

Beef production pushes equipment to its limits. High volumes, variable product sizes, and strict safety requirements make reliability non-negotiable. Every minute of downtime risks wasted product and lost revenue.

At FPEC, we design and build American-made systems that keep beef processing lines running efficiently and consistently. With more than six decades of engineering expertise, we partner with processors nationwide to deliver solutions that fit your workflow, meet USDA standards, and scale with your operation.

Why Your Beef Production Needs New Equipment from FPEC

Beef lines carry demands unlike any other protein. Processors deal with heavy carcasses, variable trim, and strict USDA oversight — all while trying to maximize yield and keep orders moving.

The margin for error is slim. A missed fat-to-lean ratio in ground beef, a breakdown during peak output, or a sanitation lapse in organ meat handling can create costly setbacks.

Additionally, beef processors manage an extensive range of products, each with its own requirements for quality and consistency. This can all present distinct challenges if you’re relying on outdated or inefficient equipment to run your line.

Product-specific concerns can range from:

- Ground Beef: Ground beef production must achieve precise particle control and repeatable fat-to-lean ratios to meet both customer and regulatory expectations.

- Organs: Organ meat processing demands sanitary handling and careful separation to preserve food safety and product integrity.

- Hanging Meat: Hanging weight considerations add another layer of complexity, as carcass size impacts throughput, line balance, and downstream planning.

- Retail Cuts: Products like steaks and round roasts call for systems that preserve product texture, appearance, and freshness through every stage of handling and packaging.

Modern beef processing requires equipment that doesn’t just run fast, but runs with precision and repeatability under these pressures. That means systems designed to handle the weight and variability of cattle products, protect product integrity through every stage, and simplify sanitation in facilities where compliance is the standard.

Our innovative, food-safe-focused systems do all that and more. Contact FPEC today to get the beef processing equipment you need to succeed.

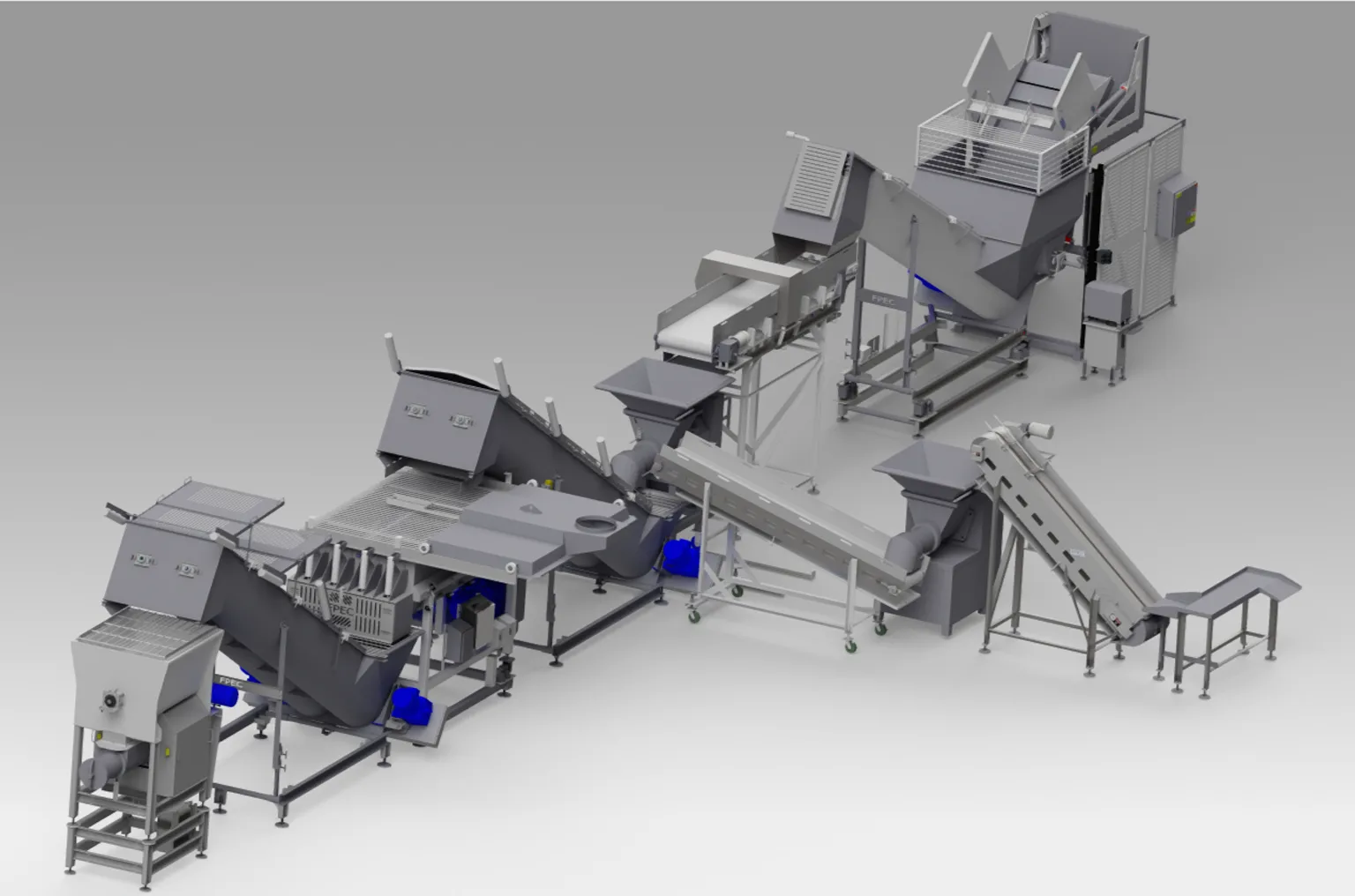

Beef Products Processing Equipment Inventory

FPEC delivers proven equipment designed specifically for beef processors. Every system is engineered to integrate seamlessly into your production environment.

Our offerings include:

Our equipment is 100% stainless steel and enables you to increase the production of safe, quality, and consistent beef products. Our inventory includes:

- Brine Mix Systems

- Cookers

- Tumblers

- Lima Separator

- Meat Press

- Mixing & Grinding

- A range of other in-stock and highly specialized machines

Moving materials and meat, like beef quarters or a beef carcass, safely and hygienically throughout your facility requires specialized systems from a partner who understands the industry.

Our material handling equipment systems:

- Conveyors

- Dumpers

- Lifts

- Spray Tunnel

- Trim Station

- Hoppers

- Product Transfer &

- Pumping Systems

- In-stock equipment & miscellaneous custom machines

Automation can help your plant overcome more than just equipment challenges. Production bottlenecks, labor shortages, and more are addressed when you implement FPEC’s automation technology into your production environments.

Our offerings include integrated control panels, fully automated lines, and everything in between. Reach out to our team, and we’ll deliver a tailored solution to meet your automation needs and achieve your operational goals.

At FPEC, we are committed to your long-term success. That’s why we provide ongoing support beyond the sale, from stocking and shipping critical replacement parts to minimizing downtime with expert maintenance services.

Whether it’s an overnight delivery or on-site assistance, we will always work alongside your team to keep production moving and ensure your systems evolve along with your plant’s goals.

About FPEC: A Partner for the Long Term

When your animal meat processing plant experiences equipment challenges, you need a partner you can trust. Since 1959, FPEC has been that partner for processors across the country.

For 66 years, we’ve remained family-owned and committed to American manufacturing. We serve beef processors with systems built to perform under pressure. Our engineering-first approach has helped customers improve throughput, eliminate bottlenecks, and maintain compliance with food safety standards.

Beyond that, we have a deep understanding of the industry, and make ongoing service and on-site support for our customers a general rule of every partnership.

Success in Every Story

Hear about how FPEC equipment has helped our customers across the country.

FPEC equipment well designed and built to last. Maintenance on FPEC equipment is easier and we have less downtime with their equipment.

When i toured the FPEC plant I was amazed the craftsmanship and was surprised how large their facility is.

FPEC surprised me that they could not only build the equipment but also they build their own controls for everything, it makes it was easier to start things up.

FPEC tumblers really pick up marination!! We have great results using these tumblers.

FPEC solved my product flow issue, they designed a layout that moves my product smoothly thru process.

Talk to the Beef Processing Equipment Experts Today

When beef production is on the line, you need more than an equipment supplier. You need a partner that understands the complexity of your operation and acts accordingly. Talk with our engineering team today to explore equipment solutions tailored to your plant’s unique needs.