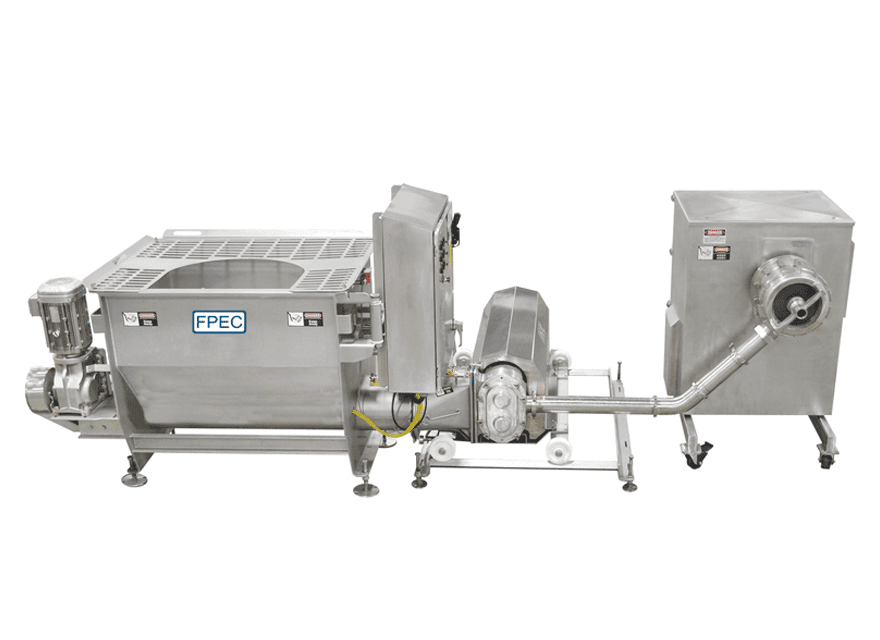

In meat and food processing, speed and consistency are critical for meeting production demands. FPEC's inline grinder system is designed to keep product moving smoothly from one stage to the next. The mounted wheel-type housing and carbide burr make this piece of processing equipment well-suited for countless production lines.

By integrating grinding directly into the production line, you can reduce downtime, improve quality control, and streamline workflows. Our inline grinding system is equipped with the latest shredder technology and can accommodate a wide range of materials, making for a smoother flow through the production line.

Streamlining the Grinding Process

Traditional grinding setups often require the product to be moved between separate machines, which can exhaust your team and slow down your operations. Increased handling time can also raise the product temperature before it's transferred to downstream equipment. These extra steps introduce safety concerns that aren't present with an inline grinder.

FPEC's inline grinding system eliminates those extra stages by positioning the grinder directly within the production line.

The mounted wheel-type housing and carbide burr can handle tough solids at a high flow rate. The abrasive capacity of our technology reduces inefficiencies, helping your facility meet its production demands. Our equipment is equipped with rugged shredder capabilities to keep food items flowing through the line.

Technical Features of the Inline Grinder System

Our inline grinder system is an efficient and powerful piece of technology. Key features include:

- Numerous installation and configuration setups available

- 500 lb–10,000lb-capacity hopper

- Variable speed pumps

- Available in single-plate, double-plate, or triple-plate configurations

- Optional bone collection

- Robust abrasive capacity to maximize product flow

Additionally, we can customize the length and configuration of your model for ease of installation and operation. The mounted wheel-type housing saves valuable floor space, while optional integrated debris collection features maintain a cleaner, more efficient production environment.

Benefits for Processing Facilities

Investing in an inline grinder with an ergonomic composite housing and free-speed carbide burr offers several benefits for your facility, including:

- Reduced handling time: Streamlines production by eliminating separate transfer steps.

- More consistent product quality: Maintains steady feed rates and allows for precise plate selection.

- Lower labor requirements: Fewer transfer points mean less manual oversight.

- Improved food safety: Minimizes temperature fluctuations and unnecessary handling.

- Faster production cycles: Supports the high-volume demands of modern processing facilities.

The large abrasive capacity and variable length of our inline shredders and grinders allow you to tailor the flow of products to meet your production demands. Our machine has the power to effortlessly shred solids while maintaining a high line flow.

Engineering and Support to Keep Your Plant Running Smoothly

At FPEC, we offer a variety of inline grinder models featuring ergonomic composite housing, heat exchangers, customizable flow rates, and the power to grind solids with ease.

FPEC inline grinders integrate seamlessly with a full range of processing equipment, including shredders, pumps, and complementary systems, engineered to deliver the power and durability required to keep production moving without interruption.

Every FPEC system is backed by a dedicated team of service specialists who understand the demands of food processing operations. Our support experts can help you troubleshoot issues, maintain your inline grinder, and clear out bones or other debris that may be impacting the efficiency of your equipment.

Videos

Playlist

Success in Every Story

Hear about how FPEC equipment has helped our customers across the country.

FPEC equipment well designed and built to last. Maintenance on FPEC equipment is easier and we have less downtime with their equipment.

When i toured the FPEC plant I was amazed the craftsmanship and was surprised how large their facility is.

FPEC surprised me that they could not only build the equipment but also they build their own controls for everything, it makes it was easier to start things up.

FPEC tumblers really pick up marination!! We have great results using these tumblers.

FPEC solved my product flow issue, they designed a layout that moves my product smoothly thru process.

Boost Efficiency With an Inline Grinder

When efficiency and reliability are top priorities, a free-speed inline grinder from FPEC is the ideal tool for the job. Our shredders, grinders, and other meat-processing equipment are built to perform and to last.

Contact us today to learn more about our inline grinder models, shredding equipment, and other machinery.