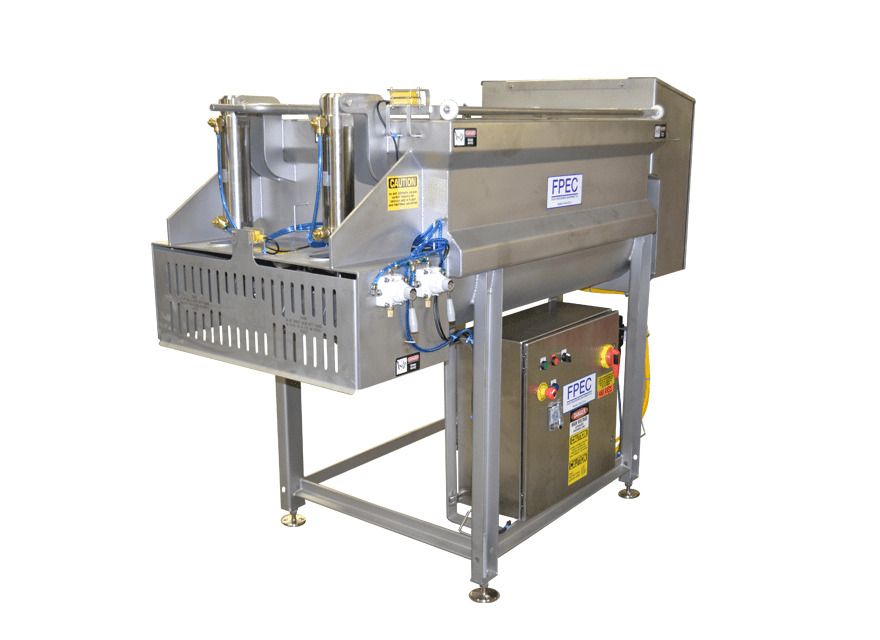

Lab Mixer

When you're in the small-scale production phase of product testing, precision is everything. FPEC's lab mixer is made to provide the same high level of performance and reliability as full-scale mixers.

Designed for testing materials and products, our lab mixing machine features a compact footprint, a variable-speed motor, and the ability to create stable emulsions reliably. It gives processors a dependable way to develop and refine products before scaling up.

Our mixer offers durability, control, and versatility for a diverse array of blending and mixing applications. Here's a closer look at the benefits our lab mixer can provide.

Supporting Product Development and Quality Control

New product creation and process improvement require accurate, repeatable results in a controlled environment. When results fail to translate from the research stage to production at scale, products often fall short of customer expectations. In a worst-case scenario, processors will have to go back to the research stage to meet key quality and consistency standards.

FPEC's lab mixer bridges this gap by allowing processors to test materials via robust blending and mixing capabilities.

Our equipment is capable of creating stable emulsions and providing consistent performance across batches. The precision controls ensure that recipes, ingredient blends, and processing parameters are perfected before large-scale rollout.

Technical Features of the Lab Mixer

Our lab mixer is a small but capable mixing unit that's durable enough for rigorous use yet compact enough for testing and verification in a research environment. Key features include:

- 50lb–500lb-capacity units

- Ribbon or paddle shafts available

- Multiple electric motor options

- CO2 option available for product cooling

- Various standard and add-on accessories

- Emulsifying attachments

- Dual-discharge doors

- 100% stainless steel construction for sanitary mixing environments

Our machine is ideal for a variety of mixing operations. Thanks to the electric lift and high-shear dispersion, it can thoroughly mix, agitate, or emulsify many different types of materials with ease.

Benefits for Processors and Product Developers

Adding laboratory mixers to your operations can provide a slew of significant benefits, including:

- Accurate replication of large-scale production processes

- Reduced ingredient waste during trials and small runs

- Faster product development with consistent, reliable results

- Improved quality control by validating recipes before full-scale production

- Versatility to handle various powders, liquids, and solids

The durable mixer offers reliable performance and adequate capacity for research and development processes. Its powerful agitators and stainless steel design provide the flexibility you need to meet your production demands.

Why Processors Trust FPEC for Laboratory Mixers

For decades, FPEC has been a trusted supplier of high-performance equipment to the food and meat industries.

Our meticulously constructed laboratory mixers are intended to solve the challenges you encounter every day. With multiple motor options, an electric lift, and an assortment of attachments, our laboratory mixers represent the top of the line.

When you invest in a lab mixer from FPEC, you can be certain that it will meet or exceed your expectations. Every model features robust mixing vessels, multiple mixers, and a powerful electric motor.

We also offer world-class customer service. Our support staff is here to help you get the most out of your laboratory mixer and troubleshoot any issues you encounter along the way.

Success in Every Story

Hear about how FPEC equipment has helped our customers across the country.

FPEC equipment well designed and built to last. Maintenance on FPEC equipment is easier and we have less downtime with their equipment.

When i toured the FPEC plant I was amazed the craftsmanship and was surprised how large their facility is.

FPEC surprised me that they could not only build the equipment but also they build their own controls for everything, it makes it was easier to start things up.

FPEC tumblers really pick up marination!! We have great results using these tumblers.

FPEC solved my product flow issue, they designed a layout that moves my product smoothly thru process.

Perfect Your Process Before Moving to Full-Scale Production

When accuracy, repeatability, and efficiency matter in product development, FPEC's lab mixer is the right choice. It enables you to fine-tune recipes and processes in a controlled environment. Once you've identified the right mix of materials, you can scale up to high-volume production.

Ready to learn more about our laboratory mixers and other processing equipment? Contact us today to discover the optimal configuration for your facility's needs and get your order underway.