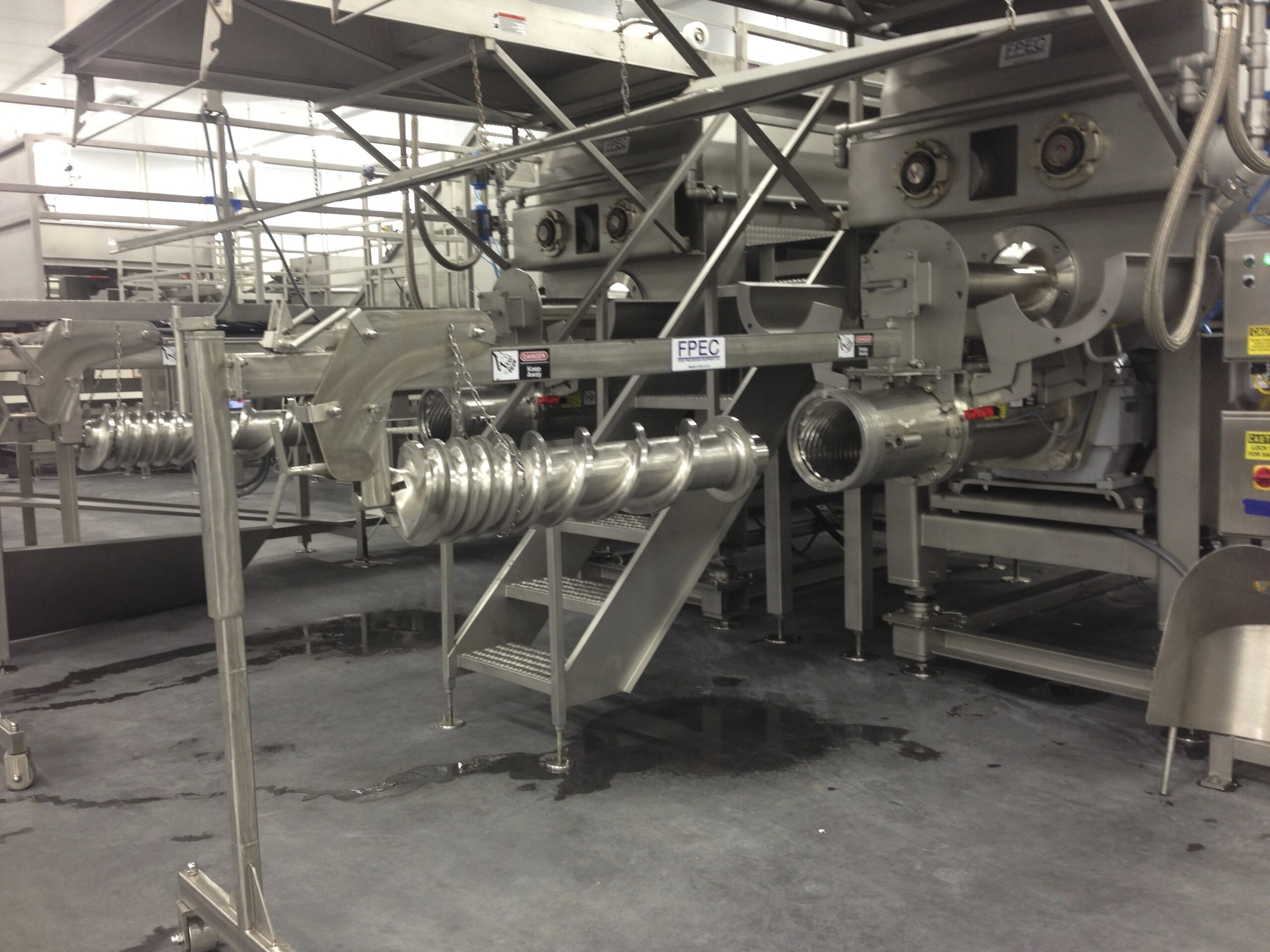

Modern food and meat processing calls for equipment that can streamline multiple stages without sacrificing quality. FPEC's mixer grinder is designed to do just that. It combines efficient mixing with precision grinding in a single, durable system.

By merging two critical stages of production, you can save time, reduce handling, and eliminate flow-breakers that hinder total productivity.

Our mixer grinder is built with performance and durability in mind. It packs the power you need to grind spices, smoothies, meats, and other food items with minimal effort. Operators will enjoy a seamless experience, while consumers will delight in consistent, high-quality products.

Combining Two Essential Processes With Our Mixer Grinde

Separating mixing and grinding into different stages often requires more handling, more space, and longer processing times. Each transfer increases the risk of unwanted product variation and operational slowdowns. Every extra stage you add to your workflow limits how much prepared product you can produce each day.

Our mixer grinder integrates these steps into one continuous process.

The stainless steel design makes it easy to use our machine as a grinder, a mixer, or both. Ingredients are distributed evenly during mixing while also preparing the product for the next stage with a uniform grind. The result is unmatched efficiency and consistency, along with reduced labor demands.

Technical Features of the Mixer Grinder

FPEC's mixer grinder is the perfect solution for your commercial kitchen or processing facility. Key features of our machine include:

- 1,000lb–6,000lb capacity

- Powerful grinder and mixer capabilities

- Formed channel legs and frame

- Intermeshing mixing paddles

- Variable speed motors

- 9"–16" diameter plate

- Fluted grinder head

- 12" diameter unload screw

- Bone-collection system

- Tightly sealed lid

- Controls designed for comfort and ease of operation

- Shaft seals retract for easy cleaning

- Safety guard over the mixing chamber with a safety interlock

Our mixer grinder can also be equipped with a CO2 chilling system to keep products within safe temperature ranges.

Benefits of Mixer Grinders for Processing Facilities

Replacing separate mixers and grinders with an all-in-one mixer grinder from FPEC can offer countless benefits, including:

- Faster processing cycles: Eliminates separate mixing stages to accelerate throughput.

- Uniform ingredient distribution: Ensures consistent flavor and appearance across batches.

- Reduced labor needs: Integrated operation lowers manual handling requirements.

- Seamless integration: Unifies mixer and grinder functions into one streamlined system.

- Improved grind consistency: Maintains steady product flow for reliable results.

- Fine, secure outputs: Product can be stored safely in stainless steel jars.

- Adaptability: Handles a wide range of proteins, blends, and recipe requirements.

Our powerful mixer grinder can free up space in your shop by replacing two pieces of machinery with a single robust, efficient solution.

Mixer Grinder Systems Backed by Six Decades of Expertise

For decades, FPEC has been providing mixers, grinders, and other food processing machinery to clients across the globe.

Our mixer grinder is specifically designed for commercial food processing applications, delivering the speed, durability, and capacity necessary for high-volume operations. We focus exclusively on meeting the high-volume production needs of processing facilities and commercial operations.

In addition to our top-of-the-line equipment, FPEC also provides dedicated customer support to ensure your system operates at peak efficiency.

From the first interaction, our experts will help you find the ideal mixer, grinder, or other piece of equipment to support your operations. After you receive your mixer grinder, you'll receive ongoing support from the knowledgeable FPEC team. We're committed to helping you maximize your new investment.

Videos

Playlist

Success in Every Story

Hear about how FPEC equipment has helped our customers across the country.

FPEC equipment well designed and built to last. Maintenance on FPEC equipment is easier and we have less downtime with their equipment.

When i toured the FPEC plant I was amazed the craftsmanship and was surprised how large their facility is.

FPEC surprised me that they could not only build the equipment but also they build their own controls for everything, it makes it was easier to start things up.

FPEC tumblers really pick up marination!! We have great results using these tumblers.

FPEC solved my product flow issue, they designed a layout that moves my product smoothly thru process.

Streamline Your Production With a Combination Mixer Grinder

Ready to upgrade your food-processing equipment? FPEC's mixer grinder is just what your facility needs. You can eliminate the disjointed operation of separate grinders and mixers to speed up production, reduce space usage, and make room for other equipment.

To learn more about our high-performance mixer grinder, contact our team today.