Food Conveyor Systems

When every shift is measured in output and every delay cuts into margin, the way your product moves matters. A dependable food conveyor system is more than a means of transport. It’s the difference between exceeding your bottom line and losing valuable money and time.

At FPEC, we design and integrate food-grade conveyors for your specific food processing workflow. Whether you're transferring bulk materials, directing portions for packaging, or managing rejects, our conveyors work in sync with the rest of your system.

Start the conversation with our team today to find the conveyor belt equipment that best fits your line.

SOLVE THE EQUIPMENT ISSUES SLOWING DOWN YOUR LINE

Stop Letting Conveyor Belt Inefficiencies Slow You Down

You know what happens when product backs up at a transition point. The upstream equipment can’t run. Labor stands idle. Downstream tasks get off schedule. These small chokepoints become big problems fast, and no one wants that phone call at 2 a.m. because a belt seized or a screw jammed.

Your plant doesn’t have time to troubleshoot around unreliable conveyors. You need systems that fit your exact process, maintain product integrity, and reduce the need for unexpected repairs. That’s what FPEC delivers.

With over half a century of experience engineering full-system material handling solutions, like our specialty conveyors, we don’t just drop in a conveyor and walk away. We look at how your product flows, how your team works, and how your plant operates—then we design the right conveyor to fit.

Our Food Grade Conveyors

FPEC conveyor systems are engineered to perform reliably in real-world food processing conditions, including wet environments, handling raw products, heavy loads, continuous use, and everything in between.

Every conveyor we build prioritizes sanitation, operator safety, and long-term durability. All are Safety Level 3 standard with or without purchase of controls, and can include UL-listed controls built in-house. These aren’t off-the-shelf systems. Each one is built to meet the performance targets and plant specifications of your food industry operation.

FPEC offers a full lineup of food conveyor systems, including:

Twin Screw Conveyor

Our screw conveyor is designed specifically with batch holding capacity in mind. It boasts a 2,000 to 10,000 lb holding capacity with two up to 30” diameter augers, and:

- Quick and efficient discharge

- Hydraulic or electric gear motors

- Direct or chain drive

- Sprocket or shaft mount drives available

- Open channel frame design

- Polished or bead blast finish

- Portable units equipped with swivel casters with brakes

- Integrated or standalone controls

Reject Conveyor

Supports quality assurance by isolating off-spec product without interrupting the main flow. Engineered for clean separation and reliable performance in high-speed environments.

Our reject conveyor is:

- Available with shuttle, gate, or manual reject options

- Available with a locking reject bin

- Available in various belt styles and configurations

- Available with stainless steel gear motor or hydraulic drive

- Made with heavy-duty construction and framework

- Built with sanitary open channel design for easy cleaning

- Featuring NEMA 4X enclosures with slope top box

- Enhanced by UL-listed controls built in-house

Pivoting Screw Conveyor

We offer fully customized solutions for our screw conveyors, including the pivoting screw conveyor. Like all our sanitary conveyors, it is made from stainless steel. It also boasts either a polished or bead blast finish and up to 30” diameter augers.

Additional features include:

- Hydraulic or electric gear motors

- Direct or chain drive

- Power pivot gives the flexibility of using one screw conveyor to load two machines

- Open channel design

- Integrated or standalone controls

Metering Screw Conveyor

With our standard 100% stainless steel fabrication and up to 24” diameter auger, our metering screw conveyor system gives a competitive edge to your food production line. Key features include:

- Hydraulic or electric gear motors

- Direct or chain drive

- Open channel design

- Holding hopper with agitator

- Polished or bead blast finish

- Integrated or standalone controls

- Can be used with load cells

- Clean out port at drive end

- Safety Level 3 standard on all screw conveyors with or without purchase of controls

Horizontal Screw Conveyor

For improved food safety and greater capacity, turn to FPEC’s horizontal screw conveyor with direct or chain drive, and the following technical options:

- Large capacity or specialty infeed hoppers available

- 6” to 30″ diameter augers

- Hydraulic or electric gear motors

- Open channel design

- Polished or bead blast finish

- Integrated or standalone controls

Gate Conveyor System

Offers responsive flow redirection and product diversion. Equipped with automated gate control, it enables efficient sorting, routing, and reject handling.

Features range from:

- PLC or with push button controls

- Any width or length

- Various belt styles and configurations

- Stainless steel gear motor or hydraulic drive

- Heavy-duty construction and framework

- Sanitary open channel design for easy cleaning

- NEMA 4X enclosures with slope top box

- All controls UL-listed and built in-house

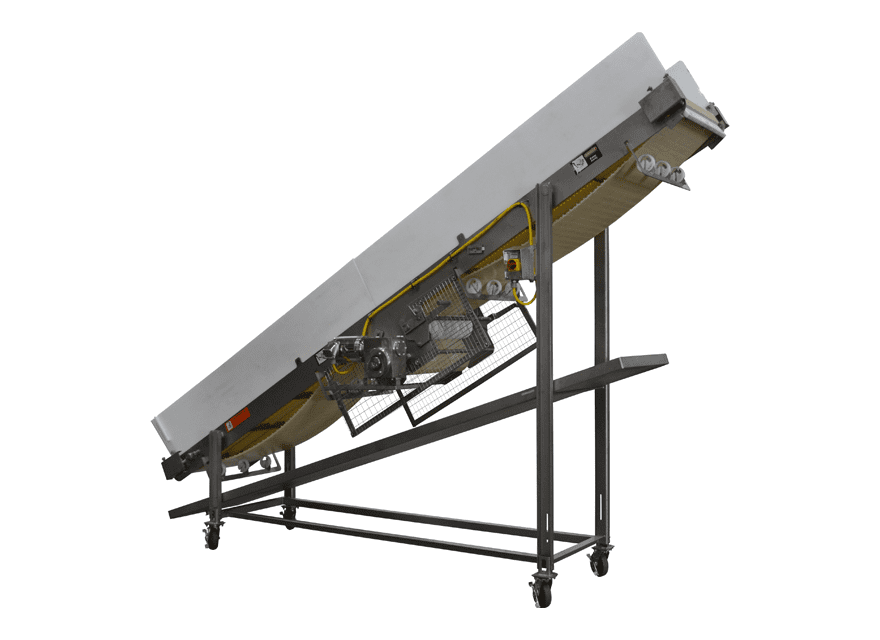

Belt Conveyor Systems

Provides smooth, sanitary transport of bulk food product across your production line. Built for durability and easy cleaning, it integrates seamlessly into multi-stage systems and can include:

- Any width or length

- Various belt styles and configurations

- Stainless steel gear motor or hydraulic drive

- Heavy-duty construction and framework

- Sanitary open channel design for easy cleaning

- NEMA 4X enclosures with slope top box

- All controls UL-listed and built in-house

Batching Screw Conveyor

Delivers controlled product flow for precise batching applications. Ideal for recipe-driven processes, our conveyor features augers with diameters ranging from 6” to 30”, regulating ingredient portions with consistency and accuracy.

It includes our standard conveyor options:

- Large capacity or specialty in-feed hoppers available

- Hydraulic or electric gear motors

- Direct or chain drive

- Open channel design

- Polished or bead blast finish

- Integrated or standalone controls

- NEMA 4X enclosures with slope top box

Accumulation Conveyor That Keeps Your Line Moving

Manages product flow by collecting items in a hopper and evenly spacing items for downstream operations. Designed to prevent line surges, it meters products to the next machine at your desired flow rate.

FPEC offers:

- Available in any width or length

- Available in various belt styles and configurations

- Available with stainless steel gear motor or hydraulic drive

- Heavy-duty construction and framework

- Load cells available upon request

- Sanitary open channel design for easy cleaning

- NEMA 4X enclosures with slope top box

- All controls UL-listed and built in-house

Metering Screw Conveyor

With our standard 100% stainless steel fabrication and up to 24” diameter auger, our metering screw conveyor system gives a competitive edge to your food production line. Key features include:

- Hydraulic or electric gear motors

- Direct or chain drive

- Open channel design

- Holding hopper with agitator

- Polished or bead blast finish

- Integrated or standalone controls

- Can be used with load cells

- Clean out port at drive end

- Safety Level 3 standard on all screw conveyors with or without purchase of controls

Twin Screw Conveyor

Our screw conveyor is designed specifically with batch holding capacity in mind. It boasts a 2,000 to 10,000 lb holding capacity with two up to 30” diameter augers, and:

- Quick and efficient discharge

- Hydraulic or electric gear motors

- Direct or chain drive

- Sprocket or shaft mount drives available

- Open channel frame design

- Polished or bead blast finish

- Portable units equipped with swivel casters with brakes

- Integrated or standalone controls

Pivoting Screw Conveyor

We offer fully customized solutions for our screw conveyors, including the pivoting screw conveyor. Like all our sanitary conveyors, it is made from stainless steel. It also boasts either a polished or bead blast finish and up to 30” diameter augers.

Additional features include:

- Hydraulic or electric gear motors

- Direct or chain drive

- Power pivot gives the flexibility of using one screw conveyor to load two machines

- Open channel design

- Integrated or standalone controls

Horizontal Screw Conveyor

For improved food safety and greater capacity, turn to FPEC’s horizontal screw conveyor with direct or chain drive, and the following technical options:

- Large capacity or specialty infeed hoppers available

- 6” to 30″ diameter augers

- Hydraulic or electric gear motors

- Open channel design

- Polished or bead blast finish

- Integrated or standalone controls

Batching Screw Conveyor

Delivers controlled product flow for precise batching applications. Ideal for recipe-driven processes, our conveyor features augers with diameters ranging from 6” to 30”, regulating ingredient portions with consistency and accuracy.

It includes our standard conveyor options:

- Large capacity or specialty in-feed hoppers available

- Hydraulic or electric gear motors

- Direct or chain drive

- Open channel design

- Polished or bead blast finish

- Integrated or standalone controls

- NEMA 4X enclosures with slope top box

Accumulation Metering Conveyor

Manages product flow by collecting items in a hopper and evenly spacing items for downstream operations. Designed to prevent line surges, it meters products to the next machine at your desired flow rate.

FPEC offers:

- Available in any width or length

- Available in various belt styles and configurations

- Available with stainless steel gear motor or hydraulic drive

- Heavy-duty construction and framework

- Load cells available upon request

- Sanitary open channel design for easy cleaning

- NEMA 4X enclosures with slope top box

- All controls UL-listed and built in-house

Belt Conveyor

Provides smooth, sanitary transport of bulk food product across your production line. Built for durability and easy cleaning, it integrates seamlessly into multi-stage systems and can include:

- Any width or length

- Various belt styles and configurations

- Stainless steel gear motor or hydraulic drive

- Heavy-duty construction and framework

- Sanitary open channel design for easy cleaning

- NEMA 4X enclosures with slope top box

- All controls UL-listed and built in-house

Gate Conveyor

Offers responsive flow redirection and product diversion. Equipped with automated gate control, it enables efficient sorting, routing, and reject handling.

Features range from:

- PLC or with push button controls

- Any width or length

- Various belt styles and configurations

- Stainless steel gear motor or hydraulic drive

- Heavy-duty construction and framework

- Sanitary open channel design for easy cleaning

- NEMA 4X enclosures with slope top box

- All controls UL-listed and built in-house

Reject Conveyor

Supports quality assurance by isolating off-spec product without interrupting the main flow. Engineered for clean separation and reliable performance in high-speed environments.

Our reject conveyor is:

- Available with shuttle, gate, or manual reject options

- Available with a locking reject bin

- Available in various belt styles and configurations

- Available with stainless steel gear motor or hydraulic drive

- Made with heavy-duty construction and framework

- Built with sanitary open channel design for easy cleaning

- Featuring NEMA 4X enclosures with slope top box

- Enhanced by UL-listed controls built in-house

FPEC helps you eliminate the weak links in your material handling chain. Whether you’re modernizing a section of your line or planning a full system overhaul, it can be custom-built to your specifications. It’s why when they call us, our customers always leave with what they need to get the job done.

The Material Handling Experts Since 1959

For more than six decades, FPEC has helped food and pet food processors build smarter, more reliable lines. Our engineering-first approach is rooted in understanding how your plant operates and how to make it work better.

We partner with you to build custom-integrated systems that address the real challenges you face on the production floor. Because we manufacture in the U.S. and maintain long-lasting partnerships with processors nationwide, you get fast access to parts, responsive service, and a team that stands behind the systems we build with dedicated service.

From design and fabrication to ongoing support, we bring a level of insight and follow-through that helps you move forward with confidence.

Success in Every Story

Hear about how FPEC equipment has helped our customers across the country.

FPEC equipment well designed and built to last. Maintenance on FPEC equipment is easier and we have less downtime with their equipment.

When i toured the FPEC plant I was amazed the craftsmanship and was surprised how large their facility is.

FPEC surprised me that they could not only build the equipment but also they build their own controls for everything, it makes it was easier to start things up.

FPEC tumblers really pick up marination!! We have great results using these tumblers.

FPEC solved my product flow issue, they designed a layout that moves my product smoothly thru process.

Make the Move Toward More Sanitary, Efficient Conveyors for Your Food Processing Line

If your current conveyor systems are slowing down your operation, talk to the experts at FPEC. We’ll help you map out exactly what your line needs to stay efficient, sanitary, and on pace.