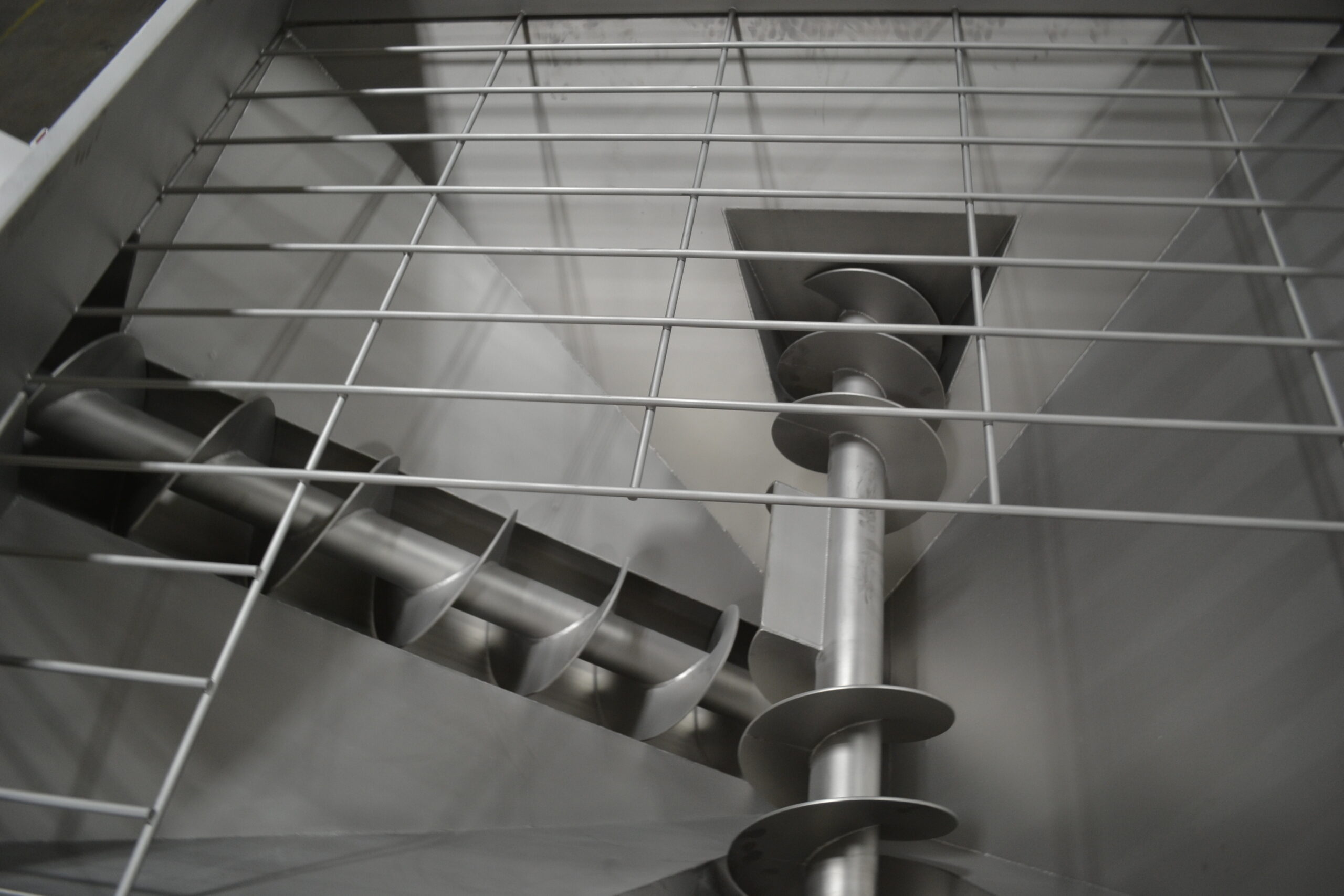

Batching Screw Conveyor

Precision in product flow starts with consistent, measured transfer between stages. When throughput depends on exact quantities at exact intervals, a generic conveyor won’t cut it. FPEC’s batching screw conveyor is engineered to deliver metered product movement tailored to your line’s timing and output targets.

Engineered Conveyance for Consistent Batching Plant-Wide

For processors balancing multiple ingredients or transitioning products between key phases, maintaining flow control is non-negotiable. FPEC’s batching screw conveyor helps you standardize delivery, reduce variance, and streamline batch preparation—without compromising speed.

It’s engineered to handle exact volumes of product with smooth, even movement, giving you tighter control over flow and timing.

Designed to support both grinding and marination systems, this conveyor is ideal for applications where batch integrity directly impacts product quality. Its controlled screw mechanism helps regulate output by weight or volume, while integrated controls communicate with upstream and downstream systems to minimize lag.

Whether installed as part of a new system layout or retrofitted to improve an existing line, every FPEC batching screw conveyor is customized to match your application and footprint. When accuracy and reliability are required to keep your operation running smoothly, this is the solution built for the job.

Mechanical Precision & High-Conveying Efficiency That Keeps You Ahead

The performance of your batching process is only as good as the equipment behind it. That’s why FPEC designs each screw conveyor for lasting performance under the pressures of daily production.

Made with stainless steel construction and engineered for hygienic washdown, the batching screw conveyor includes the following features:

- Large capacity or specialty in-feed hoppers available

- 6” to 30″ diameter augers

- Hydraulic or electric gear motors

- Direct or chain drive

- Open channel design

- Polished or bead blast finish

- Integrated or standalone controls

- Safety Level 3 standard on all screw conveyors, with or without purchase of controls

- NEMA 4X enclosures with slope top box

- All controls UL-listed and built in-house

- Custom-built to your specifications

Each unit is tailored to the type of product you’re conveying—ensuring gentle handling for marinated proteins or steady, even feed for ground formulations.

A Proven Partner in Precision Processing

For more than 66 years, FPEC has helped food processors nationwide improve their production lines with systems that prioritize reliability and control. We’re not just fabricators, we’re engineers who work closely with your team to design equipment that fits your operational goals.

When you choose FPEC, you’re gaining more than a piece of equipment. You’re gaining a partner who understands what’s at stake when your batching system goes offline. Our team supports you from the initial layout through installation, training, and long-term service.

Your line depends on accuracy. Let’s build the systems that deliver it—batch after batch.

Success in Every Story

Hear about how FPEC equipment has helped our customers across the country.

FPEC equipment well designed and built to last. Maintenance on FPEC equipment is easier and we have less downtime with their equipment.

When i toured the FPEC plant I was amazed the craftsmanship and was surprised how large their facility is.

FPEC surprised me that they could not only build the equipment but also they build their own controls for everything, it makes it was easier to start things up.

FPEC tumblers really pick up marination!! We have great results using these tumblers.

FPEC solved my product flow issue, they designed a layout that moves my product smoothly thru process.

Start a Conversation With Our Engineering Team

Tell us about your current batching challenges. We’ll help determine whether a custom screw conveyor is the right fit—or recommend an integrated system designed to meet your exact performance goals.

Reach out today to speak with an experienced FPEC engineer and move one step closer to a more controlled, consistent production flow.