Product Transfer and Pumping Equipment

Keep product moving efficiently and accurately through every stage of your process with FPEC’s engineered solutions for product transfer and pumping. Designed to maintain product integrity while maximizing output, our systems give you total control over flow rates, hygiene, and system integration.

FPEC delivers a full line of pump and vacuum transfer systems to help food processors automate movement without disrupting product consistency or compromising quality. Whether you're feeding a forming machine, portioning onto a line, or moving high volumes between systems, we’ll build a solution that fits your facility, your specs, and your production goals.

Stainless Steel Product Transfer and Pumping Systems

All equipment is 100% stainless steel and built to perform shift after shift with minimal maintenance and maximum uptime. Our inventory for the food processing industry includes:

Vacuum Transfer System Screw Conveyor

This version of our Vacuum Transfer System pairs vacuum technology with a metering screw conveyor for increased accuracy. The screw conveyor precisely meters product into the next step of your line, eliminating bottlenecks and maintaining consistent throughput.

- Vacuum transfer head and metering screw combo

- Transfer rates from 2,000 to 20,000 lb. per hour

- Portable vacuum pump system with integrated sensor controls

- PLC-based automation with Allen-Bradley components

- Fully stainless steel construction with quick-clean design

Vacuum Transfer System

Engineered for accuracy and automatic flow, FPEC’s original Vacuum Transfer System (VTS) is built to streamline downstream processes such as cooking and freezing. The entire system’s batching capabilities and PLC control ensure consistent product transfer in a clean, enclosed environment.

- Portable transfer head and vacuum pump cart

- Allen-Bradley control system with HMI

- Transfer rates up to 20,000 lb. per hour

- Built entirely from stainless steel for hygienic operation

Vacuum Metering System II

Engineered with a lower profile and improved portability, the VMS II provides all the benefits of vacuum metering in a system that’s easy to clean and move. The entire unit disassembles in minutes without tools, allowing for fast sanitation and changeover.

- Just 7 ft. tall with a 5 ft. cleaning position

- Lightweight, portable, and easy to maneuver

- Accurate scale-based vacuum metering

- Tool-free assembly and disassembly

- Allen-Bradley HMI and PLC control platform

Vacuum Metering System (VMS)

FPEC’s Vacuum Metering System (VMS) is a portable, high-volume transfer solution built to maintain accuracy and consistency. With optional Paddle Portioning, this system delivers a gentle, even dispense directly onto your conveying line.

- Transfer rates from 2,000 to 20,000 lb. per hour

- Allen-Bradley HMI and PLC-based controls

- Optional Paddle Portioning for precision portion control

- 100% stainless steel construction

- All controls UL-listed and engineered in-house

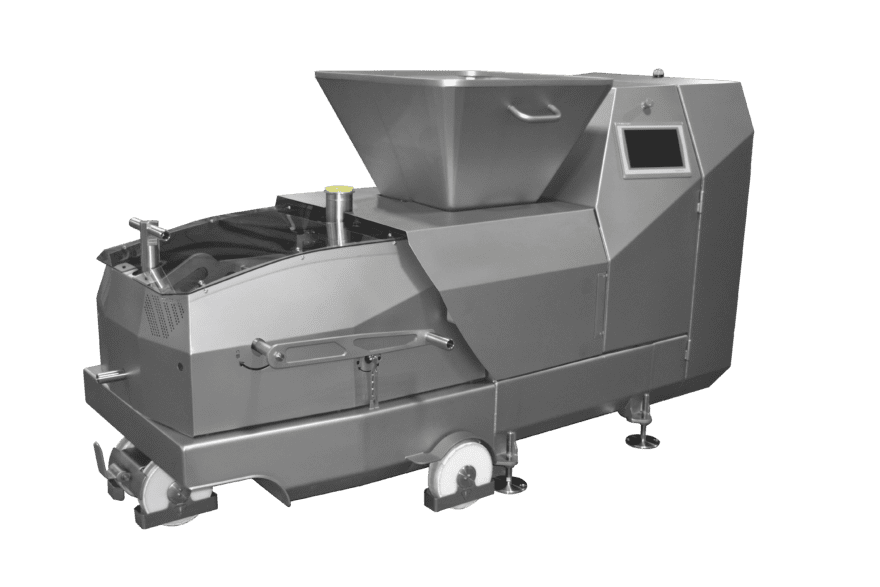

Twin-Screw Pump System

Built for viscous and hard-to-handle products, FPEC’s Twin Screw Pump System offers smooth and consistent transfer without damaging product texture. Designed with a variable-speed auger agitator, this system ensures reliable flow and prevents product bridging.

- Hopper capacities from 500 to 10,000 lb.

- Output rates up to 30,000 lb. per hour

- Twin screw stainless steel pump with variable speed control

- NEMA 4X electrical enclosure with slope-top box

- Hopper cover includes integrated safety switches

- Custom-built to match your operation

Single-Screw Pump System

Ideal for space-constrained environments or smaller chunk products, the Single Screw Pump System efficiently feeds high volumes of protein into a positive displacement pump. It maintains product integrity while delivering a consistent flow to the next processing phase.

- Output capacities up to 20,000 lb. per hour

- Hopper sizes range from 750 to 10,000 lb.

- Stainless steel construction and a positive displacement pump

- Integrated safety and UL-listed controls

- Available in custom configurations

Single Screw Vane Pump System

FPEC’s Single Screw Vane Pump System combines the steady feeding performance of a single screw system with the gentle handling of a vane pump. This setup is especially effective on sheet meat applications where shape and texture must be preserved.

- Output capacities up to 20,000 lb. per hour

- Hopper capacities from 750 to 10,000 lb.

- Stainless steel vane pump with integrated control system

- Hopper lid with built-in safety interlocks

- Fabricated entirely from stainless steel

Precision Pump System

For forming and portioning applications, the Precision Pump System offers exact flow control. With a twin screw design that compresses meat for high-efficiency forming, it delivers precision, throughput, and consistency in one package.

- Variable filling up to 14,000 lb. per hour

- Hopper sizes range from 500 to 5,000 lb.

- Minimal product degradation

- Optimized for high-speed forming lines

Positive Displacement Pump Cart

This mobile pump system is built for operations that need flexibility and reliability. The cart-based unit delivers high-volume transfer capacity with smooth, consistent operation. Designed with integrated safety and ease of cleaning in mind.

- Up to 20,000 lb. per hour throughput

- Mobile stainless steel cart with a positive displacement pump

- NEMA 4X control enclosure with slope-top box

- Custom-fabricated to match your plant layout

About FPEC: More Than An Equipment Provider

Founded in 1959, FPEC has been engineering purpose-built systems for more than six decades. We serve food processors nationwide with equipment that’s American-made, thoughtfully designed, and built to last.

We are more than a supplier. We’re a long-term partner committed to helping you eliminate bottlenecks, avoid downtime, and exceed production expectations. Our team of experienced engineers works alongside you to design integrated systems that perform every day on your line.

As a family-owned company, we believe in earning your trust with every piece of equipment we build. That’s why every transfer and pumping solution we offer is custom-engineered, fabricated from stainless steel, and backed by in-house support from a team that understands your operation from the inside out.

Success in Every Story

Hear about how FPEC equipment has helped our customers across the country.

FPEC equipment well designed and built to last. Maintenance on FPEC equipment is easier and we have less downtime with their equipment.

When i toured the FPEC plant I was amazed the craftsmanship and was surprised how large their facility is.

FPEC surprised me that they could not only build the equipment but also they build their own controls for everything, it makes it was easier to start things up.

FPEC tumblers really pick up marination!! We have great results using these tumblers.

FPEC solved my product flow issue, they designed a layout that moves my product smoothly thru process.

Build a Smarter Transfer System Today

At FPEC, every product transfer and pumping system is engineered to serve a specific role in your production line, helping you reduce labor, eliminate contamination risks, and maintain steady product flow. Whether you’re upgrading a single component or automating a full system, our engineering team is ready to build a solution that works seamlessly in your environment.

Contact our team today and get access to your ideal product transfer and pumping system.