Food Processing Dumpers

Every day, raw material needs to be moved, lifted, and dumped to keep your line productive. But when your current system introduces safety risks, requires constant maintenance, or doesn’t align with your production flow, it slows everything down.

That’s why processors turn to FPEC for dumpers that boast a higher performance and a longer lifespan. Built for heavy-duty food processing use, our dumpers are engineered for operator safety, ease of cleaning, and seamless integration with existing upstream and downstream equipment.

Contact our team today to find dumper equipment tailored to your specific meat or pet food processing application.

SOLVE THE EQUIPMENT ISSUES SLOWING DOWN YOUR LINE

The Best Way to Protect Uptime and Eliminate Risky Manual Lifting

Manual dumping creates opportunities for delays, spills, and injuries. Over time, workarounds and outdated dump stations become liabilities. When your equipment can’t handle the material load or breaks down mid-shift, your line suffers, and so does your bottom line.

When your equipment affects your goals, you can’t remain stationary. You need to act fast to get the material handling equipment that supports the pace and sanitation requirements of your modern food processing plant. With FPEC’s customized dumper systems, you can move raw ingredients and in-process material with more control, less effort, and fewer interruptions.

Our Dumpers: Engineered for Food Plant Efficiency

Whether you’re working with drums, bins, totes, or custom containers, we offer a full range of dumping systems designed for high-volume, high-compliance food processing environments.

All FPEC dumpers are built from stainless steel and designed with UL-listed controls built in-house. Every design is tailored to your specific capacity needs and plant layout, letting the equipment adapt to your existing processes, rather than forcing a fit.

Our standard dumper features, unless specified, include:

- 3,000 lb. capacity, higher capacities available

- Self-contained stainless steel hydraulic power unit

- Lifting carriage fabricated from 3/8″ thick formed plate

- Electrical components mounted in NEMA 4X enclosure with slope top box

Browse our entire lineup of food processing dumpers equipped with industry-leading innovations for the maximum benefits to your line.

Portable Lift Cart

The portable cart lift from FPEC has been specially engineered for heavy-duty use. Robust construction and multiple lifting options ensure that every unit meets the specific demands of your application.

The key features of our lift include:

- Standard dump heights of 83″ and 96″

- Custom dump heights available to meet facility-specific applications

- Max lifting capacity of 600 lbs

- 2 HP motor

- Adjustable base to accommodate flooring variations

- Elevated base allows for quick, convenient washdowns

- UL-listed controls built in-house

- 100% Stainless steel construction

Together, these features and specifications create a portable cart lift that is well-suited for demanding daily use in food-processing environments. The resulting equipment streamlines material handling and safeguards operator safety and product quality.

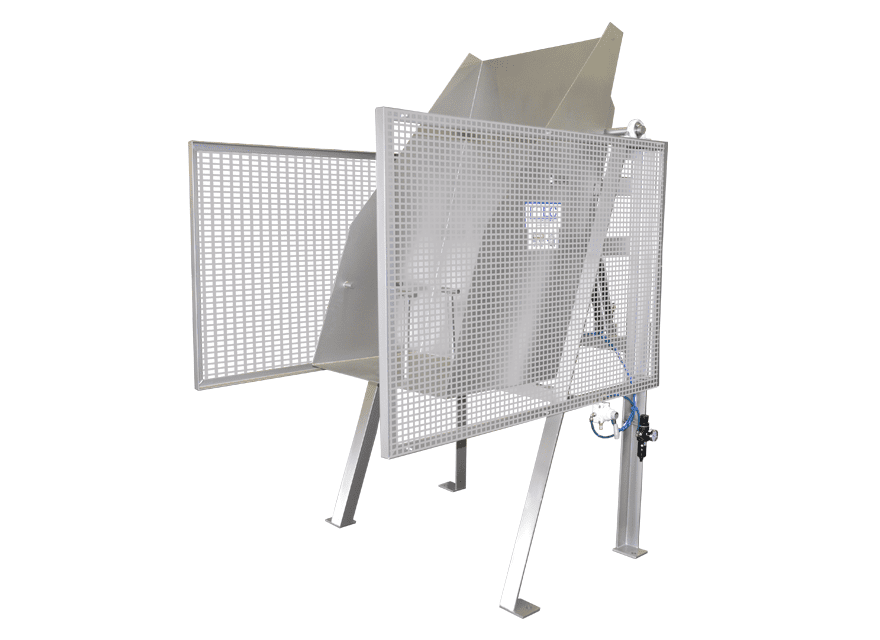

Tote Dumper

Purpose-built for smaller-load, standard tote containers, our tote dumpers offer secure, efficient dumping that minimizes product loss and maintains clean handling of raw materials. FPEC offers:

- Tote capabilities from 40 to 100 lb.

- Custom heights available

- Pneumatic, electric, or hydraulic options

- 304 stainless steel construction

- Open channel sanitary design

- Safety cage available

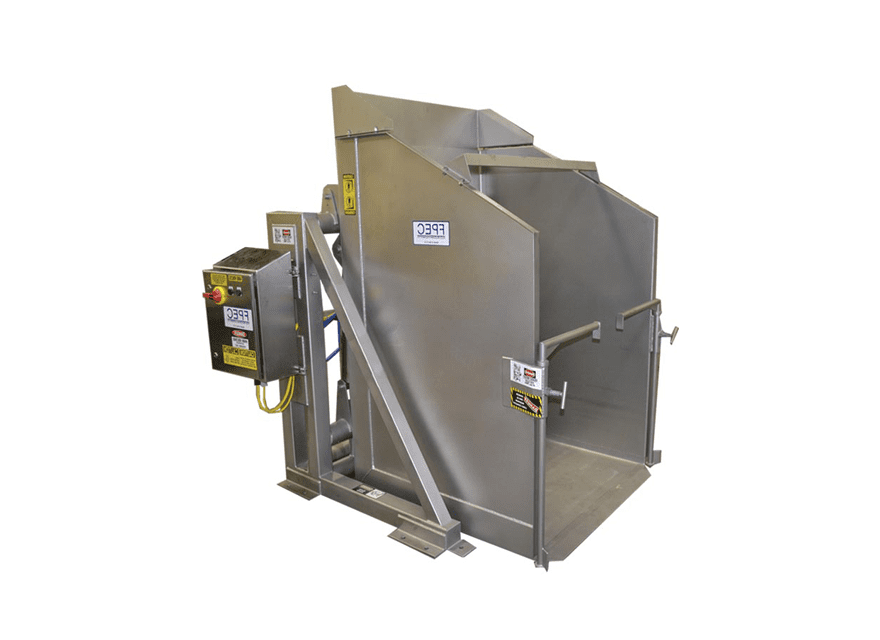

Pivot Dumper

FPEC offers four pivot dumpers of various heights so you can select the equipment footprint to fit your space and throughput capacity. Each features a pivoting design that reduces mechanical complexity while boosting performance.

Suitable for operations requiring side-dump angles or restricted vertical space, our pivot dumpers include:

- Standard pivot height options of 42”, 54”, 60”, & 70”

- Open channel available

- Manual hand valve or push button controls

- Optional anti-rocking controls

- Optional breakaway bottom

Open Channel Dumper Machine

All FPEC open channel dumpers are manufactured with all channel instead of tubing or pipe. Our machines support easy cleaning and reliable use across a variety of container styles, and include:

- Dumpers from 42” to 140” dump heights

- Side load option available

- Heavy-duty construction

- Optional anti-rocking controls

- Optional breakaway bottom

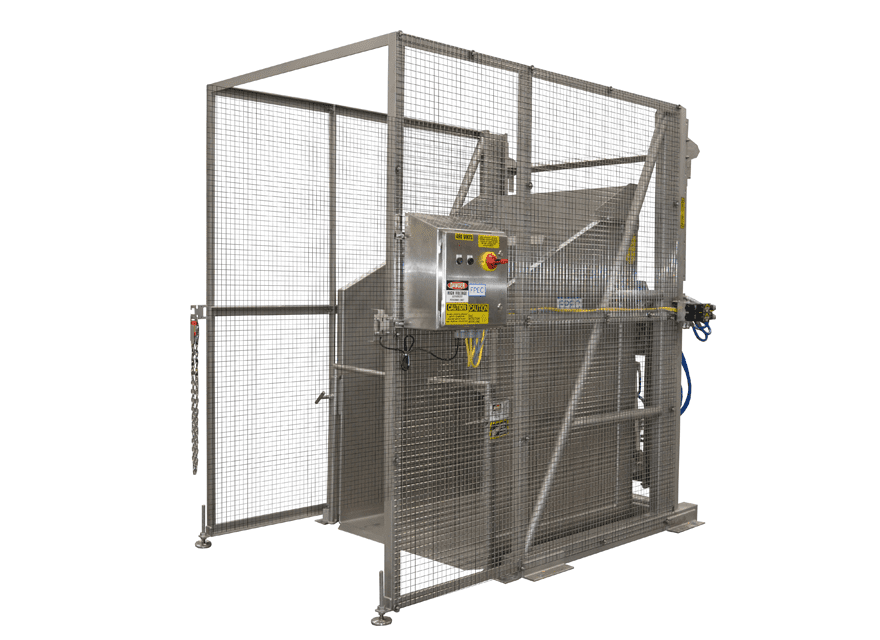

Hylift Dumper

Engineered for improved ergonomics and operator safety with extended lift height capability, this dumper is frequently used in operations where clearance is required to reach over hoppers or equipment.

Key features include:

- Adjustable dumping height from 74″ to 84″

- Lift and pivot style dumper elements

- Optional anti-rocking controls

- Optional breakaway bottom

- Anti-rocking controls are standard on breakaway bottom dumper configurations

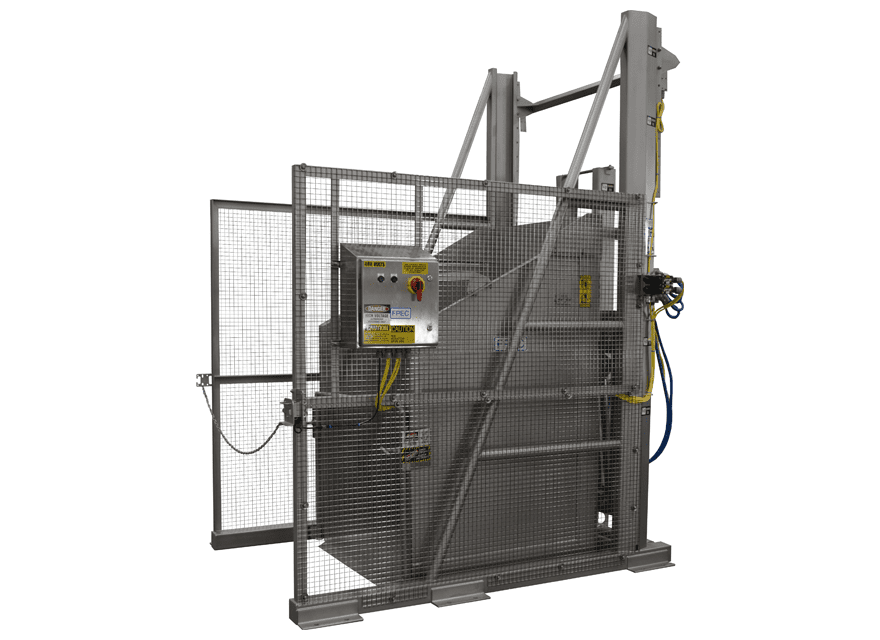

Chain Dumper Lift

Built for repetitive, high-volume dumping needs with vertical lift & tilt functionality and robust chain drive support. Ideal for heavy loads that require elevated dumping, our chain lift dumper offers the following features:

- Adjustable dumping height from 84″ to 140″

- Lift and pivot style dumper elements

- Optional anti-rocking controls

- Optional breakaway bottom

Engineering Experience You Can Rely On

Since 1959, FPEC has partnered with meat and pet food processors to design, build, automate, and integrate production systems that perform under pressure. As a family-owned company headquartered in the U.S., we stay invested in the long-term performance of your operation.

Every dumper we build is developed for real-world use in active processing environments. Our engineering team works directly with yours to get on the same page from the start, taking the time to understand your goals, layout, and line requirements. That involvement continues well beyond delivery. Whether it’s installation support, parts sourcing, or a service call, the same team that built your equipment is ready to support it for the long run.

Because we manufacture and fabricate in-house, we control every detail: materials, build quality, timelines, and technical performance. There’s no waiting on overseas components or third-party approvals. When something needs to move fast, we move with it.

Processors across the country trust FPEC not only for our equipment, but for our follow-through. We’re here to keep your line running—today, tomorrow, and for every shift after.

Success in Every Story

Hear about how FPEC equipment has helped our customers across the country.

FPEC equipment well designed and built to last. Maintenance on FPEC equipment is easier and we have less downtime with their equipment.

When i toured the FPEC plant I was amazed the craftsmanship and was surprised how large their facility is.

FPEC surprised me that they could not only build the equipment but also they build their own controls for everything, it makes it was easier to start things up.

FPEC tumblers really pick up marination!! We have great results using these tumblers.

FPEC solved my product flow issue, they designed a layout that moves my product smoothly thru process.

Let’s Talk About Your Dumper Needs

If your dumping process is slowing down production or putting unnecessary strain on your team, don’t wait for the worst outcome to happen. Avoid the costs of downtime and delays with FPEC.

We’re here to provide the equipment you need to succeed. Talk to our engineers today about your current pain points, and we’ll help you map out a dumper system that supports your goals.