Food Processing Lifts

When moving heavy products or raw materials, manual handling is a critical but risky process. Labor fatigue, repetitive strain, and slow transfers create friction at every point in the line if you’re relying on manual labor or outdated systems.

You need material handling equipment that moves with precision and supports your workflow, not slows it down. That’s where FPEC’s specialized lifts come in. Engineered specifically for demanding food processing environments like your plant, our lift systems keep your product and your line moving at all times.

Every piece of FPEC lift equipment is designed for real production floors with reliability, sanitation, and safety in mind. Get in touch with our team to learn more about our custom offerings and find the lift that fits your unique needs.

SOLVE THE EQUIPMENT ISSUES SLOWING DOWN YOUR LINE

When Lift Capacity & Performance Slow You Down, FPEC Equipment Moves You Forward

Every minute counts during production. When operators are tied up manually transferring product or your existing equipment breaks down, you're risking injury, inconsistency, and even downtime.

Your operation requires equipment that works alongside your team, built to handle the daily demands of high-throughput food processing. FPEC lift systems are designed to integrate easily with your current layout and eliminate bottlenecks and inefficiencies.

We collaborate directly with processors like you to engineer lifting systems that match your goals—whether that’s improved ergonomics, higher throughput, or safer product handling.

Our Lift Lineup

FPEC offers a full range of heavy-duty lifts designed to improve workflow and reduce wear on your crew. Whether stationary or portable, automated or manual, each model is made to perform in the specific conditions of your facility.

Standard features for our top-tier lift systems include:

- 100% stainless steel fabrication

- UL-listed controls built in-house

- Custom specifications & add-ons

- Electrical components mounted in NEMA 4X enclosure with slope top box

Our available lifts include the following systems.

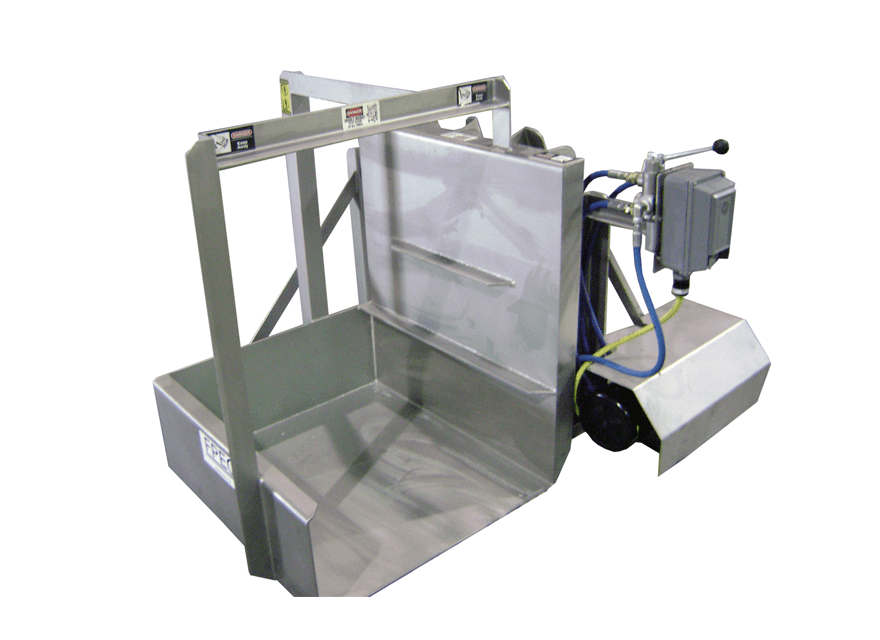

Tilt Cart System

We engineered our convenient cart tilter with lasting durability and ease of use in mind. Every unit is built to meet a variety of operating requirements in the most demanding manufacturing environments.

Notable features of our cart tilter include:

- Maximum lifting capacity of 600 lbs

- Reliable 2 HP power pack

- Single-station carriage

- Open-channel frame

- Heavy-duty pins and bushings

- NEMA 4X enclosures with slope-top box

- UL-listed controls built in-house

All FPEC equipment is engineered for dependable performance, helping you keep operations running smoothly while protecting worker safety.

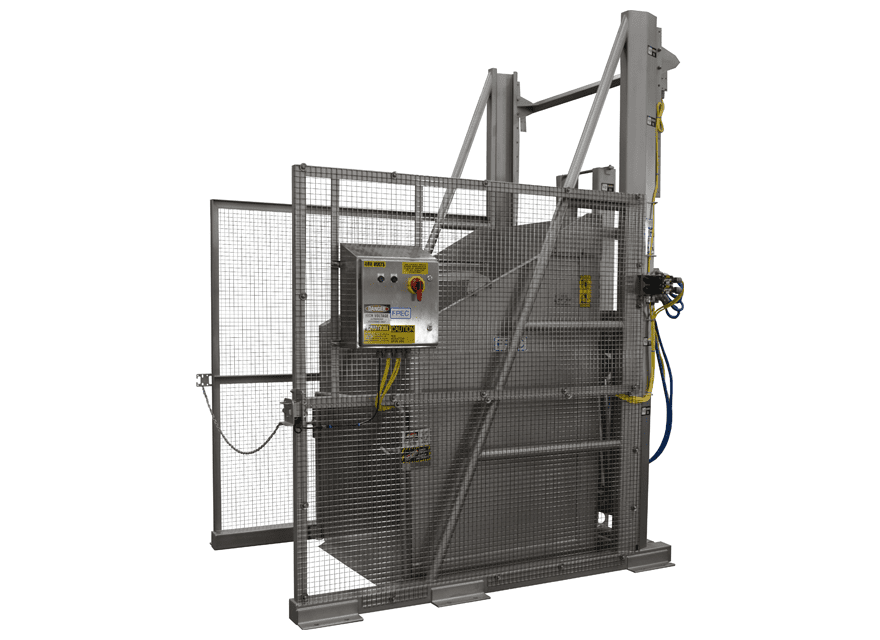

Stationary Lift

Our lift improves ergonomics and safety by raising carts to a fixed dump height, allowing for efficient and repeatable unloading of product. It’s a dependable addition for any plant looking to streamline material transfer with minimal manual handling.

The equipment boasts:

- Dump height of 83″

- Maximum lifting capacity of 600 lb.

- Chain lift mechanism

- 2 HP motor

- Adjustable to accommodate floor variations

- Elevated base for easy cleaning

- 100% stainless steel fabrication

- NEMA 4X enclosures with slope top box

- All controls UL-listed and built in-house

Hydraulic Pallet Lift

FPEC’s hydraulic pallet lift is equipped with features intended to enhance your operational efficiency and safety. Here’s what you can expect from our lift tables:

- 3,000 lb lifting capacity

- Vertical lift heights range from 30″ to 48″

- Keeps pallets at a safe and comfortable working height

- Three-horsepower self-contained stainless steel hydraulic unit

- 100% stainless steel fabrication

- Custom-built to your specifications

We understand the difficulties you’re up against, which is why we built our hydraulic lift tables to make accessing stock easier and safer for your team.

Chain Dumper Lift

Our chain dumper lift includes the following standout features:

- Accommodates 3,000 lbs of products or more

- 100% stainless steel fabrication and self-contained stainless steel hydraulic power unit

- Capable of dumping products at various heights and angles

- Adjustable height from 84″ to 140″

- Anti-rocking controls available to reduce the risk of tilting or leaning

- Breakaway bottom available

Our machine is designed to handle a variety of dumping tasks to move products with ease. We offer a higher-capacity option and can adjust the height as needed to ensure that your dumper meets your requirements.

Barrel Lift

Our vertical drum lifter has been carefully engineered to ensure safe lifting, accurate positioning, and sanitary operation. Our goal is to make material-handling tasks in your operation as straightforward as possible.

Standout features of our barrel lift include:

- Standard dump heights of 83″, 96″, and 120″

- Custom lifting options to suit unique line layouts and floor plans

- Variable attachments available for barrels, totes, and carts for safe lifting in a range of applications

- Lift can be mounted on existing equipment to integrate seamlessly with your process

- 2 HP motor provides powerful, fast, and consistent lifting with a maximum weight capacity of 600 lbs

- Dependable chain lift mechanism stands up to repetitive lifting cycles

- Elevated base allows for user-friendly cleaning beneath the unit

- UL-listed controls built in-house for reliability and safety during operation

- NEMA 4X enclosures with slope top box

- 100% stainless steel fabrication

Your team can count on our barrel lifting devices’ unparalleled strength and flexibility to suit any number of operational needs.

Each FPEC lift system helps you check an item off your equipment to-do list so you can focus on running your production with greater confidence and peace of mind that every material handling machine is working the way it’s supposed to.

Equipment Backed by Unrelenting Customer Service Commitment

The team behind your equipment matters. That’s why processors across the country have chosen FPEC for all their equipment needs since 1959. As a family-owned company with a nationwide presence, we’ve built our reputation on performance, partnership, and long-term support.

We don’t send you a product and disappear from the job. Our engineers stay involved throughout your project—from planning and buildout to installation and beyond. Because we manufacture and fabricate in-house, you’ll never be left waiting on outsourced parts or support.

We know what downtime costs. That’s why FPEC lift systems are designed with long-term durability, field serviceability, and seamless integration in mind. We help you get ahead of lifting inefficiencies, so you can focus on producing.

Success in Every Story

Hear about how FPEC equipment has helped our customers across the country.

FPEC equipment well designed and built to last. Maintenance on FPEC equipment is easier and we have less downtime with their equipment.

When i toured the FPEC plant I was amazed the craftsmanship and was surprised how large their facility is.

FPEC surprised me that they could not only build the equipment but also they build their own controls for everything, it makes it was easier to start things up.

FPEC tumblers really pick up marination!! We have great results using these tumblers.

FPEC solved my product flow issue, they designed a layout that moves my product smoothly thru process.

Talk to Our Team About the Right Lift for Your Line

If your current lifting processes are creating bottlenecks or safety concerns, it’s time to make a change. Contact FPEC to speak with an expert about what your plant needs to keep production flowing and your team protected.