Industrial Mixer, Grinders, & Blending Equipment

Mixers, grinders, and other blending systems are key pieces of your food processing line. When ground meat production slows down due to unsafe or low-quality equipment like this, every aspect of your business suffers.

Put inconsistent blends, unexpected breakdowns, and capacity bottlenecks in the past with FPEC. FPEC mixer/grinders offer heavy-duty performance in a variety of high-volume environments. Built to integrate directly into your workflow, our systems deliver uniform mixes and reliable particle size control, so you can worry less about your line and more about your operational goals and growth.

Ground Meat Mixers & Grinders That Keep Pace With Your Plant

Your plant doesn’t slow down, so your mixing and grinding systems can’t either. Every batch has to meet exacting standards for texture, blend, and temperature control, because even minor inconsistencies can trigger costly rework or product loss.

When equipment struggles to keep pace, you’re left managing downtime instead of moving product. FPEC mixer grinders are built for these realities.

Each mixer and grinder combines rugged stainless steel construction with an operator-friendly design and easy sanitation access. Controls are intuitive, allowing your team to keep production flowing without unnecessary complexity. From maintaining food safety standards to streamlining changeovers between proteins, our equipment is designed to work the way your plant works.

We understand that every operation has its own set of challenges. That’s why our engineering team doesn’t take a one-size-fits-all approach. Whether you’re scaling up output or experimenting with new formulations, we create equipment that supports your objectives—not the other way around.

Our Mixers: The Muscle Behind Your Line

Your operation deserves equipment that adapts to your proven processes. That’s why FPEC offers a full line of mixers to support everything from small-batch testing to industrial-scale production.

Here’s our full mixer lineup:

- Mixer: A dependable standard for consistent blends and accurate portions across varied formulations.

- Vacuum CO₂ Mixer: Controls temperature during processing to maintain product quality.

- Intermeshing Mixer: Dual-paddle design for thorough, efficient mixing on large volumes.

- Lab Mixer: Scaled for small-batch testing without sacrificing performance standards.

- Single Shaft Mixer: Compact, streamlined option for straightforward mixing needs.

- Massage Blender: Ideal for applications that require gentle blending without overworking proteins.

- Mixer Grinder: Combines mixing and grinding into one system for efficiency, durability, and space savings.

Find the FPEC mixer that will add the most efficiency to your line—contact our experts today.

Vacuum CO2 Commercial Mixer

Our commercial mixer with vacuum CO2 capabilities includes the following notable features:

- 250lb–12,000lb capacity

- Paddle agitators

- Hydraulic operated vacuum lid

- Constant vacuum pressure during blending cycle

- High vacuum levels

- Vacuum loading available

- Shaft seals retract for easy cleaning

- Split shaft seals available

- Pneumatic-operated discharge doors

- Electric or hydraulic drives

Additionally, our commercial dough mixers have the power and speed required to perform industrial-grade kneading, whipping, and blending. We also include several additional attachments to give you full control over your product consistency and thickness. The versatility of our units is second to none.

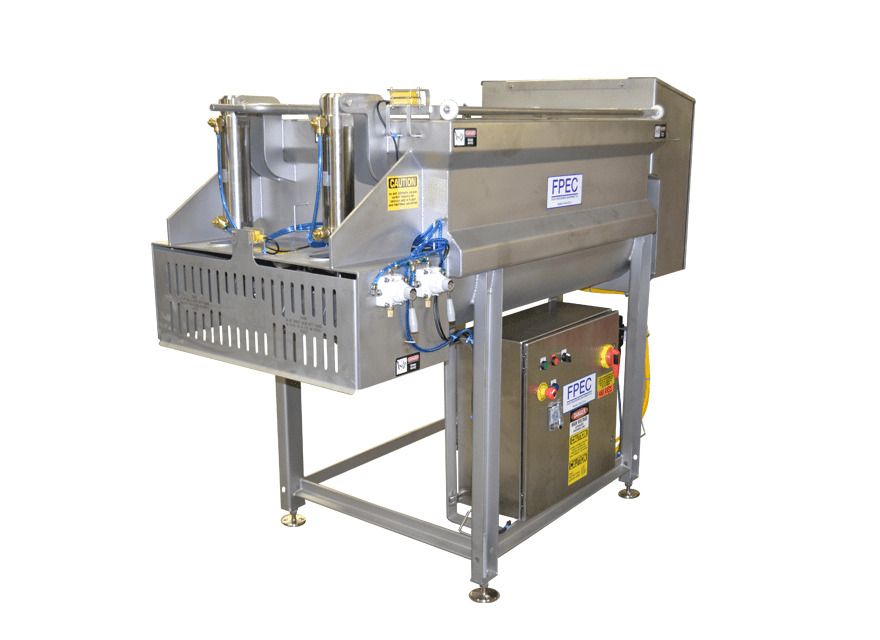

Single-Shaft Commercial Meat Mixer

FPEC meat mixers are manufactured to meet the demands of industrial production. Key features of our meat mixer grinder include:

- 250lb–6,000lb capacity

- Paddle or ribbon agitators

- Stainless steel design to promote sanitation

- Retractable shaft seals for easy cleaning

- Pneumatic-operated discharge door

- Electric or hydraulic drive options

- Allen Bradley HMI

- Controls built entirely in-house

- Ability to mix a large number of different meat and food products

When you use our meat mixers, you’ll save valuable labor hours and get more done each day.

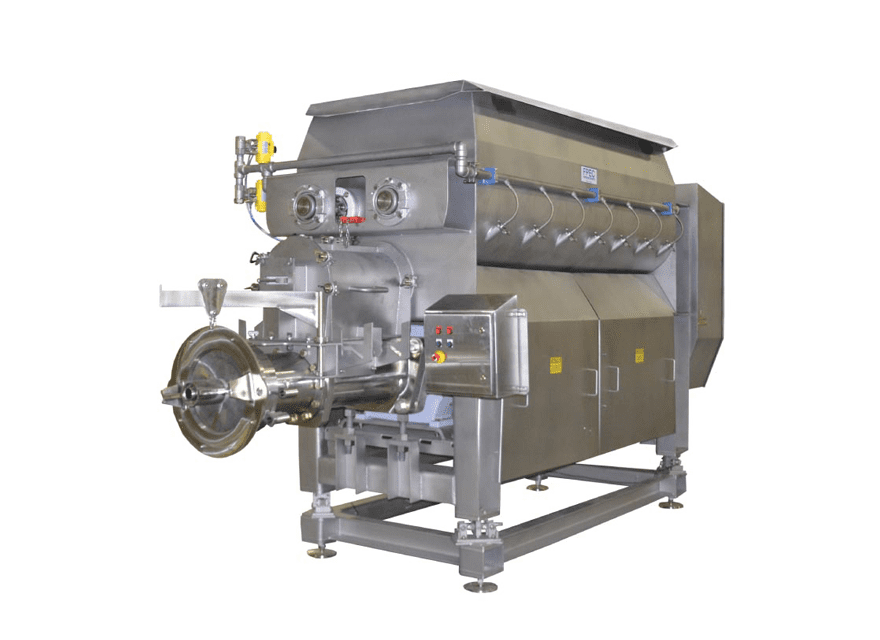

Mixer Grinder

FPEC’s mixer grinder is the perfect solution for your commercial kitchen or processing facility. Key features of our machine include:

- 1,000lb–6,000lb capacity

- Powerful grinder and mixer capabilities

- Formed channel legs and frame

- Intermeshing mixing paddles

- Variable speed motors

- 9″–16″ diameter plate

- Fluted grinder head

- 12″ diameter unload screw

- Bone-collection system

- Tightly sealed lid

- Controls designed for comfort and ease of operation

- Shaft seals retract for easy cleaning

- Safety guard over the mixing chamber with a safety interlock

Our mixer grinder can also be equipped with a CO2 chilling system to keep products within safe temperature ranges.

Massage Commercial Blender

Our commercial blender is loaded with performance- and precision-enhancing features, including:

- 250lb–12,000lb capacity

- Paddle or ribbon agitators

- Hydraulic vacuum lid

- Constant vacuum pressure during blending cycle

- Efficient operation

- Vacuum loading available

- Retractable shaft seals for easy cleaning

- Electric or hydraulic drives

- Safety guard over the mixing chamber

- Stainless steel design

A user-friendly control panel provides operators with complete control over mixing speed and power, allowing for consistent results and dependable performance in demanding commercial applications.

Lab Mixer

Our lab mixer is a small but capable mixing unit that’s durable enough for rigorous use yet compact enough for testing and verification in a research environment. Key features include:

- 50lb–500lb-capacity units

- Ribbon or paddle shafts available

- Multiple electric motor options

- CO2 option available for product cooling

- Various standard and add-on accessories

- Emulsifying attachments

- Dual-discharge doors

- 100% stainless steel construction for sanitary mixing environments

Our machine is ideal for a variety of mixing operations. Thanks to the electric lift and high-shear dispersion, it can thoroughly mix, agitate, or emulsify many different types of materials with ease.

Intermeshing Mixer

FPEC mixers are built for performance, durability, and sanitation. Our system is packed with features that align with the demands of industrial-scale processing, such as:

- 250lb–12,000lb batch capacity

- Intermeshing paddle designed for more aggressive mixing action

- Well-suited for sausage

- Paddle agitators can accommodate a diversity of materials

- Split shaft seals available

- Shaft seals retract for easy cleaning

- Pneumatic-operated discharge doors

Our mixers also feature 100% stainless steel construction, powerful rotors, and an easy-to-clean system design.

By mixing materials at precise speeds, our equipment yields consistent batches and smooth compounds. The chamber is designed with sanitation in mind, making it possible to offer your customers high-quality products with a consistent taste every time.

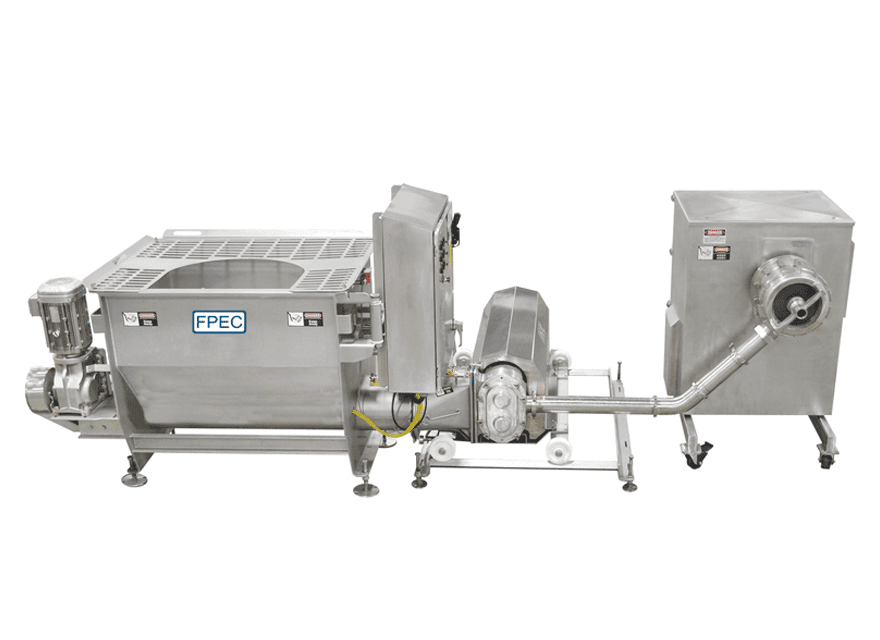

Inline Grinder System

Integrates seamlessly into your line for consistent results that allow production to continue on schedule.Don’t let particle control slow you down. Put an FPEC grinder on your floor and experience the difference of efficient equipment.

Industrial Mixer

Our industrial mixer offers a range of features designed to meet the demands of restaurants, commercial bakeries, and numerous other high-volume operations. Key features include:

- 250lb–12,000lb capacity

- Paddle or ribbon agitators

- Shaft seals that retract for easy cleaning

- Split shaft seals available

- Pneumatic-operated discharge doors

- Standard handles and accessories for superior performance

- 100% stainless steel construction

Unlike commercial countertop mixers, our industrial floor unit boasts the power and capacity to support your production needs. It can accommodate a nearly endless array of food items for unparalleled versatility and efficiency.

Commercial Meat Grinder Self-Feeding Hopper

FPEC grinders deliver particle control and throughput to meet today’s rigorous production demands. Our engineering-first approach ensures every grinder supports sanitation requirements and operates with intuitive controls that minimize training time and error.

Our grinder designs include:

- Grinder with Self-Feeding Hopper: Simplifies product flow and reduces manual handling, adjusting speed depending on production requirements.

- Inline Grinding System: Integrates seamlessly into your line for consistent results that allow production to continue on schedule.Don’t let particle control slow you down. Put an FPEC grinder on your floor and experience the difference of efficient equipment.

Engineering Excellence Backed by Six Decades of Experience

FPEC brings more than 66 years of expertise to every system we build. As a family-owned company, we’ve earned trust not only by delivering dependable equipment but by standing alongside our customers as long-term partners in their success.

That commitment goes well beyond the sale. Our engineers work with you from concept to integration, and beyond.

When your equipment is running on your food processing floor, our nationwide service network, responsive technical support, and readily available replacement parts will keep it running for the long term. If an equipment issue threatens the line, we move quickly because we understand what downtime costs.

Choose FPEC for mixers, grinders, and other food processing equipment that works.

Success in Every Story

Hear about how FPEC equipment has helped our customers across the country.

FPEC equipment well designed and built to last. Maintenance on FPEC equipment is easier and we have less downtime with their equipment.

When i toured the FPEC plant I was amazed the craftsmanship and was surprised how large their facility is.

FPEC surprised me that they could not only build the equipment but also they build their own controls for everything, it makes it was easier to start things up.

FPEC tumblers really pick up marination!! We have great results using these tumblers.

FPEC solved my product flow issue, they designed a layout that moves my product smoothly thru process.

Schedule Your Call with FPEC

When you need equipment that blends accurately, handles your throughput, and fits into your process without complications, contact FPEC. We deliver the equipment you need to succeed, when and where you need it most.